Seamless Steel Pipe

Diameter Range: 1/2” to 26”

Wall Thickness: SCH 10 to SCH 160

End Types: Beveled ends, Plain ends

Length: 20FT, 40FT, or customized as needed

Protection Caps: Plastic or iron for enhanced protection

Surface Finishes: Natural, Varnished, Black Painting, 3PE, FBE, and other coatings tailored for various environments and requirements.

Seamless steel pipe is a type of pipe that is manufactured without any seams or welds. This is achieved through a process called extrusion or rotary piercing, where a solid round steel billet is heated and then formed into a hollow tube. The absence of seams makes seamless pipes stronger and more durable compared to welded pipes, as they are less likely to fail under pressure or stress.

Key Characteristics of Seamless Steel Pipes:

- Strength: Seamless pipes can withstand higher pressures and are less prone to leaks.

- Versatility: They are used in various applications, including oil and gas, construction, and manufacturing.

- Corrosion Resistance: Depending on the material and coating, seamless pipes can offer good resistance to corrosion.

- Sizes and Specifications: They come in various sizes and can be produced to meet specific standards, such as ASTM, API, and ISO.

Seamless steel pipes are commonly used in industries where high strength and reliability are critical, such as in the transportation of fluids and gases, structural applications, and high-pressure systems.

Seamless Steel Pipe Product Overview

- Standard: API SPEC 5L (Latest Edition)ASTM A106, ASTM A53, ASTM A333, ASTM A335, ASTM A213

- Grades: B, X42, X52, X56, X60, X65, X70, and sour service grades (e.g., X70QS)

- Dimensions: Outer diameter (OD) from 1/2” to 26”

- Wall Thickness: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160

- Ends Type: Beveled ends, Plain ends

- Length: 20FT (6 meters), 40FT (12 meters), or customized lengths available

- Surface Treatments: Natural, Varnished, Black painting, FBE, 3PE

- Protection: Plastic or iron caps for end protection

- Clad and Lined Pipes: CRA Clad or lined pipes available (Carbon steel with cladding or lined alloy steel)Seamless steel pipes provided by Octal are manufactured using advanced piercing and rolling processes, which eliminate the need for welding, ensuring a uniform structure that can withstand extreme conditions. The absence of weld seams greatly reduces the risk of structural failure, making these pipes particularly useful in high-pressure and high-temperature applications.The seamless construction also results in a smoother internal surface, reducing friction during fluid and gas transport, which is particularly valuable in industries like oil and gas. The result is a highly efficient pipe that minimizes resistance and optimizes the flow of materials, helping to reduce energy consumption in transport systems.At Octal, we ensure that our seamless steel pipes are produced with precision and meet the most stringent industry standards. Our pipes are used across a wide range of industries including oil & gas, chemical processing, power generation, and infrastructure projects, each requiring specific properties to handle different operational challenges.

Industry-Leading Applications

Seamless steel pipes from Octal offer an industry-leading solution for high-stress applications. Their ability to handle fluctuating pressures and temperatures makes them indispensable in critical infrastructure projects. For example:

- Oil and Gas Exploration: Seamless pipes are used for transporting crude oil, natural gas, and refined products over long distances, often under extreme environmental conditions.

- Power Generation: Used in power plants to transport steam and other fluids under high temperatures and pressures, ensuring safety and reliability in energy production.

- Chemical Processing: Seamless pipes resist corrosive chemicals and high temperatures, making them ideal for transporting hazardous materials.

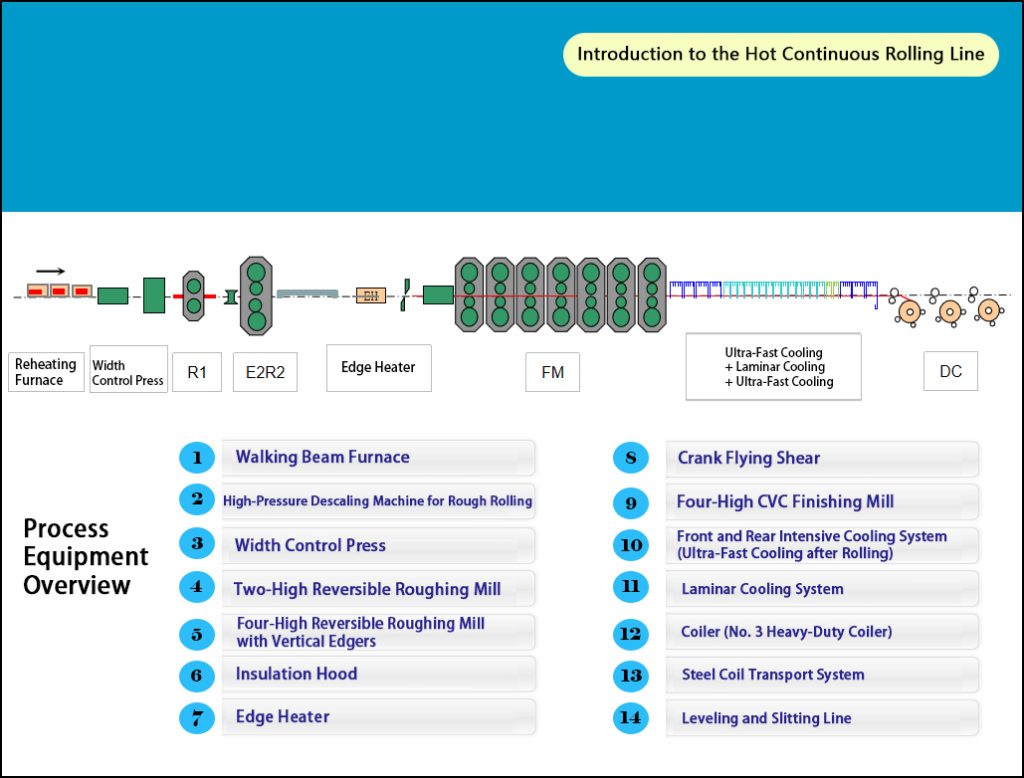

Seamless Steel Pipe Manufacturing Process

Octal seamless steel pipes are produced using both hot rolling and cold drawing processes, depending on the application requirements. The manufacturing process starts with a solid steel billet, which is heated and pierced to form a hollow tube. This is then rolled and stretched to achieve the desired dimensions and mechanical properties.

Hot Rolling

Hot rolling is typically used for larger diameter pipes. It ensures uniform thickness and mechanical properties throughout the length of the pipe. The process also enhances the grain structure of the steel, improving its toughness and resistance to stress. Octal’s hot-rolled seamless pipes are ideal for high-pressure applications where strength and durability are paramount.

Cold Drawing

Cold drawing is used for precision applications where tighter tolerances and surface finishes are required. This process increases the strength and hardness of the pipe while ensuring smooth internal and external surfaces. Octal cold-drawn pipes are used in critical applications such as hydraulic systems, where precision is essential.

By leveraging both processes, Octal provides seamless steel pipes that are not only strong and durable but also highly precise, making them suitable for a wide range of applications.

Chemical Composition of Seamless Steel Pipe

Seamless steel pipes are categorized into Carbon Seamless Steel Pipes and Alloy Seamless Steel Pipes, each offering distinct chemical compositions tailored to specific applications. The chemical elements in these pipes significantly influence their mechanical performance, including strength, durability, and resistance to corrosion or high temperatures.

Carbon Seamless Steel Pipe Composition

Carbon seamless steel pipes consist primarily of iron with carbon as the main alloying element. Carbon content is a critical factor in determining the strength and hardness of the steel, with the amount of carbon typically ranging from 0.02% to 2.1%. Based on carbon content, carbon steel can be further classified into:

- Low Carbon Steel (Mild Steel): Contains up to 0.25% carbon, making it highly ductile, weldable, and ideal for applications requiring flexibility, such as pipelines, structural components, and low-pressure systems.

- Medium Carbon Steel: With 0.25% to 0.6% carbon, this category offers increased strength and hardness, commonly used in machinery parts and moderate-stress applications.

- High Carbon Steel: Typically contains 0.6% to 1.0% carbon, providing high strength and hardness but less ductility, suited for heavy-duty uses like cutting tools or high-strength structural supports.

Additionally, carbon seamless steel pipes contain small amounts of other elements:

- Manganese (Mn): Typically between 0.30% to 1.50%, enhances toughness and wear resistance.

- Phosphorus (P) and Sulfur (S): Kept below 0.050% to reduce brittleness and improve overall ductility and weldability.

These compositions provide carbon seamless steel pipes with a good balance between strength and cost-effectiveness, making them suitable for general construction, oil and gas transportation, and medium-pressure applications.

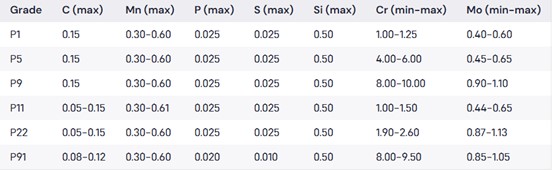

Alloy Seamless Steel Pipe Composition

Alloy seamless steel pipes include additional alloying elements beyond carbon to significantly enhance mechanical properties such as high-temperature strength, corrosion resistance, and toughness. For a seamless steel pipe to be classified as an alloy pipe, it must contain a minimum alloy content typically above 1.0% of elements like chromium, molybdenum, nickel, or vanadium.

Key alloying elements include:

- Chromium (Cr): Present at 0.3% to 12%, providing increased corrosion resistance and hardness, especially in stainless steel grades.

- Molybdenum (Mo): Generally 0.2% to 1%, improves high-temperature strength and enhances resistance to corrosion in harsh environments.

- Nickel (Ni): Content typically ranges from 0.3% to 5%, offering superior toughness and strength, particularly in low and high-temperature applications.

- Vanadium (V), Tungsten (W), and Titanium (Ti): These elements are added to further enhance wear resistance, strength, and durability at elevated temperatures.

Alloy seamless steel pipes are often used in more extreme environments, such as power plants, refineries, and chemical plants, where enhanced mechanical properties and corrosion resistance are critical. Unlike carbon steel, there is no strict upper limit on alloy content, allowing for customized grades that meet specific performance needs.

Mechanical Properties of Seamless Steel Pipes

The mechanical properties of seamless steel pipes vary according to the steel type and composition. Below are the typical strength ranges for Carbon Seamless Steel Pipes and Alloy Seamless Steel Pipes, with specific grade values provided for reference.

Carbon Seamless Steel Pipe Mechanical Properties

The mechanical properties of carbon seamless steel pipes improve with grade level. Here are the yield and tensile strength ranges for various API 5L grades (MPa):

- API 5L Grade B: Yield strength 245 MPa, tensile strength 415 MPa, suitable for low-pressure transport.

- API 5L X52: Yield strength 360 MPa, tensile strength 460 – 630 MPa, widely used for medium-pressure pipelines, often in oil and gas.

- API 5L X65: Yield strength 450 MPa, tensile strength 535 – 760 MPa, suitable for high-pressure pipelines, meeting high-strength requirements in oil and gas.

- API 5L X70: Yield strength above 485 MPa, tensile strength from 570 to 760 MPa, suitable for high-pressure pipelines.

Elongation: The elongation for carbon seamless pipes is typically between 10% and 25%. Higher-grade carbon steels offer increased strength but slightly reduced ductility.

The combination of strength and flexibility makes carbon seamless steel pipes ideal for oil and gas transportation, structural support, and mechanical components, offering cost efficiency and suitability for moderate to high-pressure environments.

Alloy Seamless Steel Pipe Mechanical Properties

Alloy seamless steel pipes are defined by their chemical composition, mechanical properties, and specific standards. These pipes excel in environments where corrosion resistance and moderate strength are required, with standards primarily governed by ASTM A335 and ASTM A213.

Key properties for ASTM A335 alloy seamless steel pipes include:

Typical Yield Strength: Typically ranges from 200 to 400 MPa, depending on the specific alloy grade and conditions. High-strength alloy steels can achieve values significantly above this range, making them particularly suitable for applications subjected to extreme pressure and impacts.

Chemical Composition and Grades: Key grades and their chemical properties include:

Elongation: Alloy steels generally exhibit elongations between 10% and 18%, providing necessary toughness while maintaining high hardness and strength.

Applications:Alloy seamless steel pipes are essential in several key industries. In oil and gas, they provide high corrosion resistance for pipelines. For power generation, these pipes ensure reliability under high temperatures and stress. In chemical processing, they effectively handle corrosive substances. In construction, they offer enhanced durability for structural support.

In conclusion, the mechanical properties of seamless steel pipes, categorized as either carbon or alloy steels, reflect their suitability for specific applications while meeting industry standards for strength and durability.

Seamless Steel Pipe Manufacturing Process

Octal seamless steel pipes are produced using both hot rolling and cold drawing processes, depending on the application requirements. The manufacturing process starts with a solid steel billet, which is heated and pierced to form a hollow tube. This is then rolled and stretched to achieve the desired dimensions and mechanical properties.

Quality Testing

At Octal, we maintain rigorous quality control throughout the manufacturing process to ensure that every pipe meets or exceeds industry standards. Each pipe undergoes multiple tests to verify its mechanical integrity, dimensional accuracy, and overall performance.

- Hydrostatic Testing: This ensures that each pipe can withstand the internal pressures it will face during operation. Every pipe is tested to ensure there are no leaks or weaknesses that could compromise its performance.

- Ultrasonic Testing: Ultrasonic waves are used to detect internal defects such as cracks or voids, which could weaken the pipe. Octal uses this non-destructive testing method to ensure the highest level of quality.

- Tensile Testing: Pipes are subjected to tensile stress to measure their strength and elongation, ensuring they meet the required mechanical properties for their specific grade and application.

Through rigorous testing and third-party certification, Octal guarantees the reliability and durability of every pipe, ensuring it meets the highest quality standards in the industry.

Applications and Packaging of Seamless Steel Pipes

Seamless steel pipes provided by Octal are utilized across various critical industries such as oil and gas, power generation, chemical processing, and construction. Their robust construction, high-pressure tolerance, and corrosion resistance make them ideal for transporting fluids, gases, and chemicals over long distances in extreme conditions. These pipes are also essential for structural supports in large-scale construction projects, including bridges and high-rise buildings, where strength and stability are paramount.

To ensure safe delivery, Octal packages its seamless pipes with protective caps and offers multiple packaging methods, including bundling and custom wooden crates, depending on the size and type of pipes. Our global logistics network supports efficient shipping to over 50 countries, ensuring that products arrive securely and on time, tailored to each project’s specific requirements.