ASTM A213/SA213 T9, T11, T22, T91 Alloy and Stainless Tubing

Octal supply ASTM A213 tubing (seamless) in common grades T9, T11, T22, T91, T92 of alloy material, grades TP304L and TP316L of stainless steel.

ASTM A213 (ASME SA213) tubing has been widely used in high temperature services especially for the boiler and superheater. Tube material could be in alloy steel and stainless steel, and manufactured in seamless of hot rolled or cold drawn. so this pipe usually used in very important places and the price is much higher than normal carbon pipes. Common grades are T9, T11, T12, T21, T22, T91 and stainless grades in TP304 or TP316.

A213 Standard Scope

As ASTM Defines: “This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated grades T5, TP304, etc. Which is listed in tables 1 and 2.

View here for ASTM A213 standard specification.

The size range for this tube is from internal diameter 1/8 inch and up to 5 inch OD. Thickness from 0.015 to 0.500 inch (0.4 mm to 12.7 mm). Also if for other size required, it could be specified in the order, also should be stated with minimum and average thickness.

Referred documents for manufacturing ASTM A213 tubing

ASTM A262 Instructions for investigating susceptibility to intergranular attach in stainless steel

A941 Terminology relating to steel, stainless steel, alloys and ferroalloys

A1016M Common specification for ferritic alloy steel, austenitic alloy steel, and stainless steel tube

E112 Test methods for determining average grain size

Referred AWS specifications

A5.5/A5.5M Specifications of Low alloy steel eletrodes for shielded metal arc welding

A5.23/A5.23M Alloy steel fluxes for Submerged Arc Welding

A5.28 Refer to gas shielded arc welding.

A5.29 Refer to flux cored arc welding.

Material Grades

For ASTM A213 low alloy steel tube including the grades ASTM A213/ASME SA213 T2, T5, T5b, T5c, T9, T11, T12, T17, T21, T22, T23, T24, T36, and ASTM A213 T91, ASTM A213 T92, T122, T911, and covers the Austenitic and Ferritic stainless steel, in ASTM A213 TP201, TP202, XM-19, TP304, TP304L, TP304H, TP304N, TP304LN, TP309S, TP309H, TP309LMoN, TP309Cb, TP309Hcb, TP310S, TP310H, and TP316, TP316L, TP316H, TP316Ti, TP316N, TP316LN, TP317, TP317L, TP321, TP321H, and etc. For more grades please review the standard of ASTM A213. These are applied at the high temperature environment, for example to used at over heat exchanger and re-heat exchanger.

What does H means in ASTM A213

For A213 Grades that contained letter H, is not the same than the material in same grade without H. With H it means higher creep-rupture strength.

Chemical and Mechanical Data Sheet of A213/SA213 Tubing

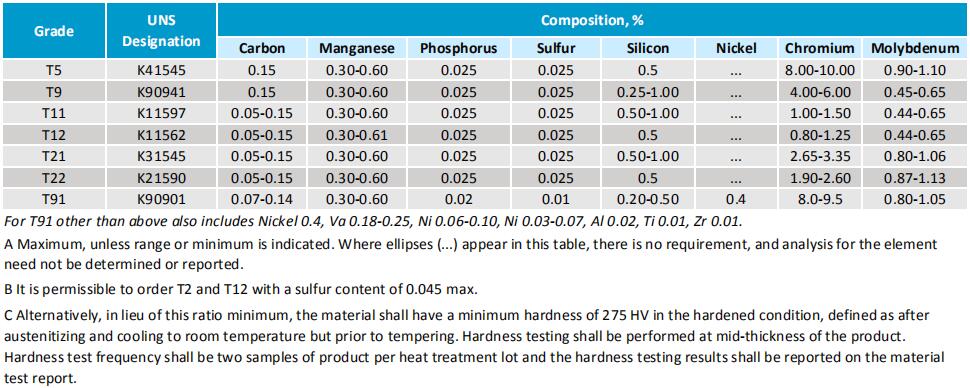

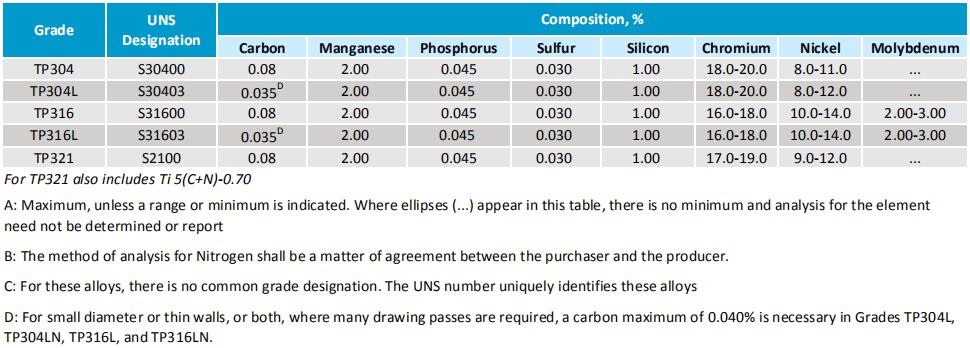

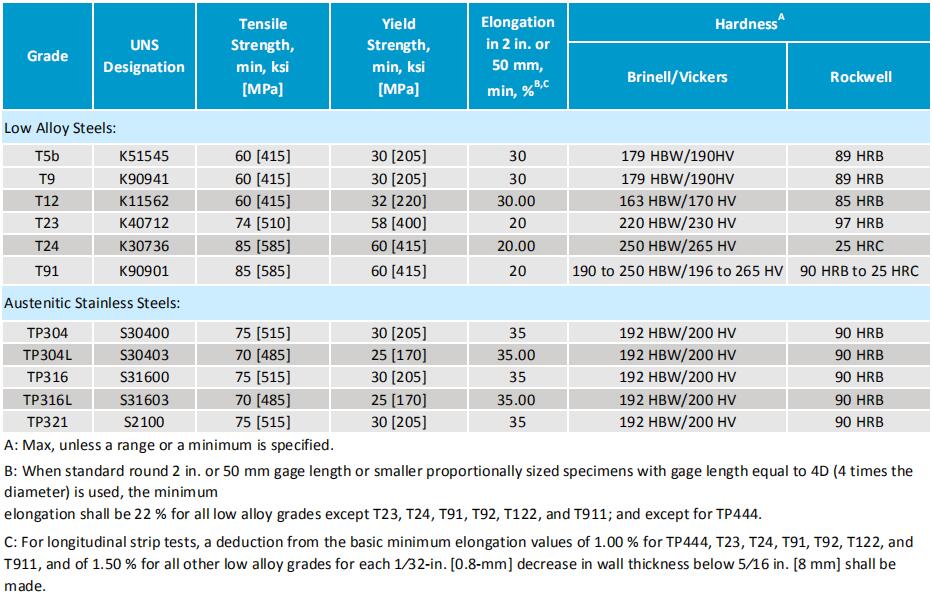

View below of ASTM A213 tubing chemical composition in table 2, mechanical properties in table 4.

Table 2: For ASME SA213 T11, T22 etc of alloy tubing

Chemicals for A213/SA213 stainless tubing

Table 4: Mechanical Properties

Heat treatment types for common grades

a. For grades T9, T11, T22, heat treatment methods are full or isothermal anneal, normalize and temper. (For conditions in later option, tempering temperature for T9 and T22 is above 675℃, T11 is above 650℃.)

b. For grades T91, T92, shall be normalize and temper, where normalizing shall be above 1040℃, tempering shall be above 730℃. As the delivery conditions.

Tolerances

Permissible variations from the specified minimum wall thickness shall be in accordance with Specification A1016/A1016M.

For Hot Formed Tubes

A: t = specified wall thickness D = specified outside diameter

For Cold Formed Tubing

Permissible variations from the specified average wall thickness shall be +/- 10 % of the specified average wall thickness for cold formed tubes

and, unless otherwise specified by the purchaser, shall be in accordance with above table for hot formed tubes

Octal supply range for ASTM A213 Tube

Standard: ASTM A213/ASME SA213 for alloy and stainless steel tube and pipe

Grade: T9, T11, T22, T91, T92, TP304/L, TP316/L, TP317/L, TP321/H etc

OD: 1/8” to 16”. 3.2mm to 406mm

WT: 0.015” to 0.500”, 0.4mm to 12.7mm

Length: 10ft, 20ft, 40ft, or customized length