API 5L X70 Pipe Specification

Standard and Grades: API 5L X70 (Q, M, QS, MS)

Product Specification Level: PSL1, PSL2, Sour Service

Manufacturing types: Seamless and welded

Outer Diameters: Seamless up to 24”, welded up to 48”

Thickness Schedule: up to SCH 160

API 5L X70 pipe is a premium grade piping material in API 5L standard specifications. Also called L485 pipe, as it’s yield strength minimum in 485 Mpa (70,300 psi). API 5L X70 covers manufacturing types in seamless and welded (ERW, SAW) types, both applied for oil and gas transmissions.

It contains two product specification levels PSL1, PSL2. (Including the material for sour services uses in PSL2)

Manufacturing Types

Seamless: Covers hot rolled seamless and cold drawn seamless.

ERW: Electric Resistance Welded

LSAW: Longitudinal Sub-merged Arc Welding

SSAW: Spiral Sub-merged Arc Welding

HSAW / DSAW: Same with SSAW for spiral welded pipe

Our Supply Range

Grade: API 5L X70 (Q, M, QS, MS)

Level: PSL1, PSL2, NACE and Sour Service (API 5L X70MS/QS)

OD range: Seamless up to 24 inch, welded up to 48 inch.

Wall Thickness Schedule: Schedule 20, SCH 40, SCH STD, SCH XS, SCH 80, SCH 120, SCH XXS, SCH 160

Length: 20ft (6m), 40ft (12m), SGL (Single Random Length), DRL (Double Random Length)

Pipe Coatings: Black Painting, Oil Varnished, FBE, 3PE, Lined and Clad

Suffix Letter Means

R: As rolled

N: Normalizing rolled, Normalized formed, Normalized

Q: Tempered and quenched

M: Thermomechanical rolled or thermomechanical formed

S: Sour Service Use

Features

API 5L X70 steel pipe has a minimum yield strength of 70,300 psi or 485 Mpa. The current X70 steel pipe are all controlled micro-alloyed carbon-manganese steels. The micro-alloys elements are mainly Nb, V and Ti, and the total content of micro-alloys does not exceed 0.15%. Therefore, the structure of the pipe is composed of acicular ferrite and bainite, and it generally has good welding performances.

Advantages:

a. High strength

b. High resistance to dynamic tearing

c. High low temperature impact toughness

d. Low ductile-brittle transition temperature

e. Acid service suitability

f. Economy and long lasting

Its excellent performance is due to the ultra-low carbon acicular ferrite structure, high density dislocations interact with fine precipitation phases.

X70 Pipe Specifications

API 5L Grade X70 Pipe Data Sheet Download in PDF

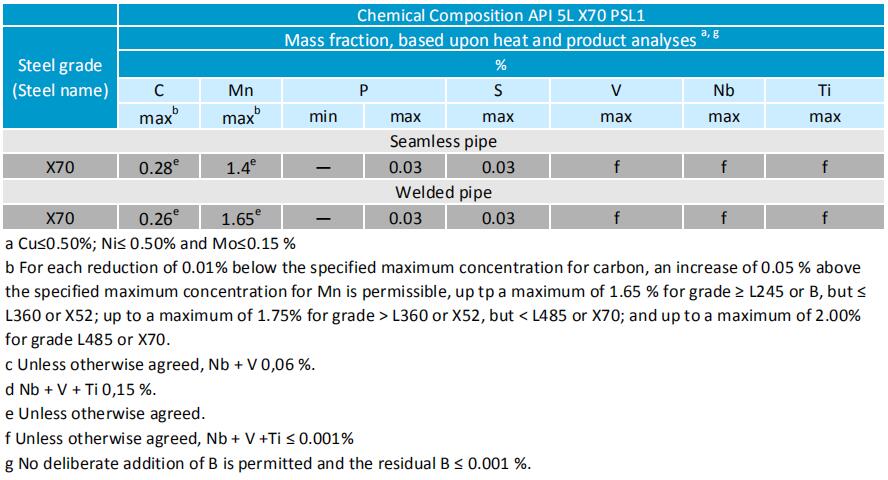

For API 5L X70 PSL1

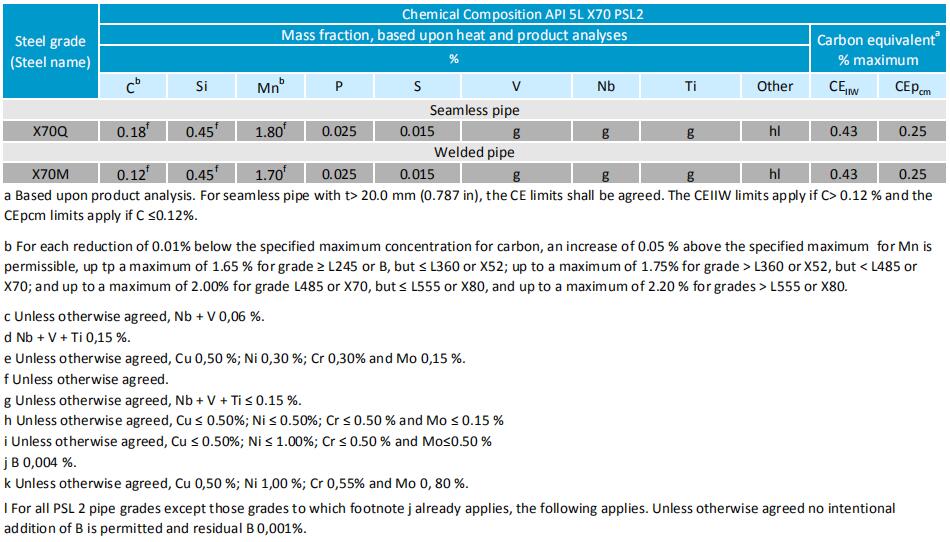

For API 5L X70 PSL2

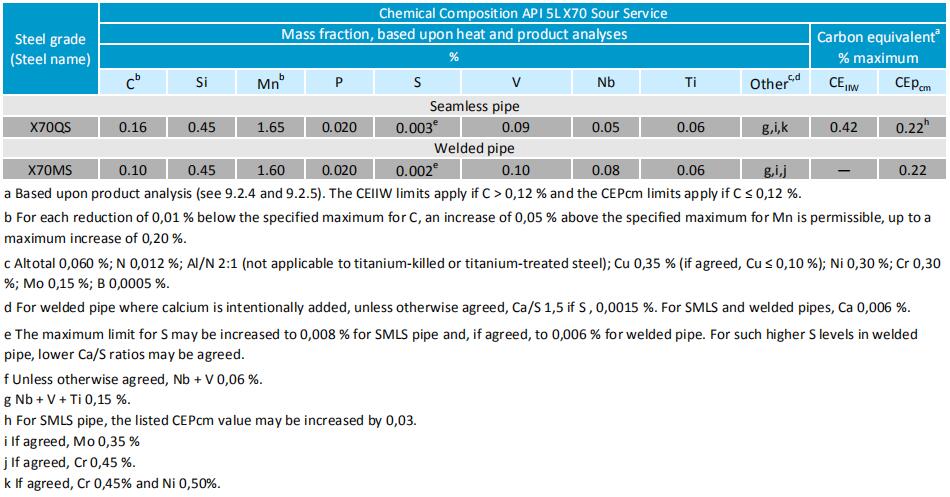

For API 5L X70 Sour Service

Mechanical Properties

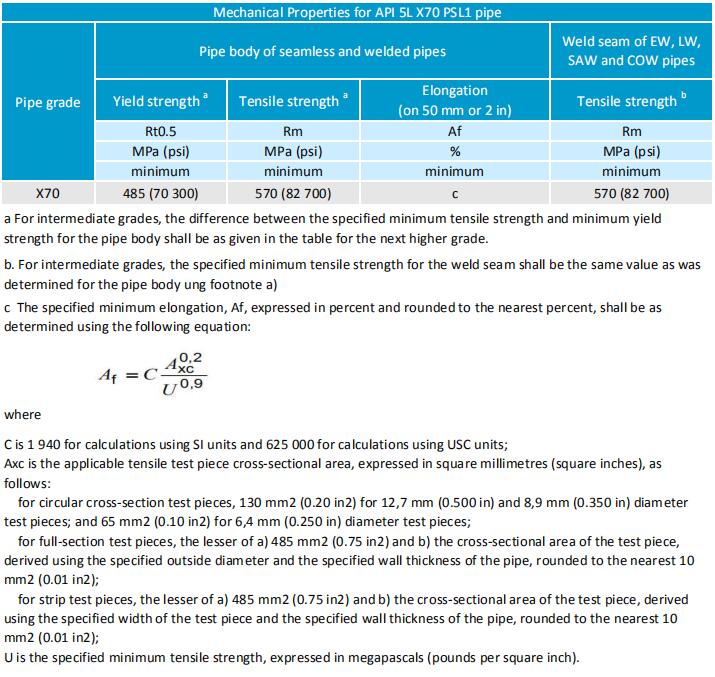

For X70 PSL1

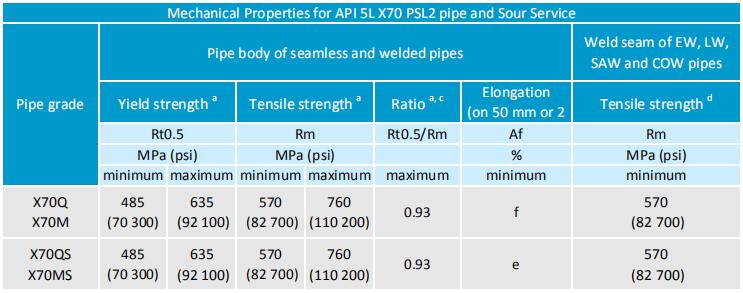

Fox X70 PSL2 and Sour Serivce

API 5L X70 line pipe has high compressive strength, compatible with super low temperature environment with excellent weldability.

Manufacture Notes

The ingots, blooms, billets, coils or plate used in the manufacture of pipe shall be made by the following processes:

Basic Oxygen process

Electric Furnace Smelting process

Open Hearth process method combined with Ladle Refining process

Tests Referred API 5L X70 pipe

Hydrostatic Test: The pipe under API 5L X70 shall perform the hydrostatic test without leakage 100%.

Bend Test: Cracks should not occur in any part of the sample and opening of weld shall not occur as well.

Flattening test: Flattening test is used to prove the pipe performances under deformation. It shall show the resistance to longitudinal cracking and circumferential cracking, including internal and external defects.

Guided-bend test: Fracture completely; Reveal any cracks or ruptures in the weld metal longer than 3.2 mm, regardless of depth. Or reveal in parent metal, HAZ or fusion line longer than 3.2mm or deeper than 12.5% of wall thickness.

CVN impact test (Performed for PSL2 pipe including pipe body tests, pipe weld and HAZ tests)

DWT test (For PSL2)

API 5L X70 PSL2

The raw material of PSL2 steel pipe should be fine grained killed steel. And the coil or steel plate used for manufacture of PSL2 steel pipe should not have any repair welds.

API 5L X70 Sour Service

API 5L X70MS or X70NS are especially for sour service uses in H2S environment. Corrosion is the main cause of pipeline leakage, and hydrogen damage is the most serious corrosion problem in pipelines. Numerous statistics show that under the action of medium containing wet H2S, oil and gas pipelines are prone to hydrogen damage. pipeline hydrogen damage have two main forms: hydrogen induced cracking (HIC) and stress corrosion cracking (SCC).

Sour Service Test Referred Standard

NACE TM 0284-Evaluation of pipeline and Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking

NACE TM 0177-Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments