API 5L X65 Pipe

Standard and Grades: API 5L X65 Q/M/MS/QS

Product Specification Level: PSL1, PSL2, Onshore and Offshore

Material for Sour Services: Low Carbon and Sulfur, for sour service, complied to NACE MR 0175

Working Conditions: H2S corrosion

Manufacturing processes: Seamless and welded (ERW, LSAW vs SSAW HSAW, DSAW)

OD range: 1” to 48”.

Common Dimension Schedule range: SCH 20, SCH 40, SCH STD, SCH 80 SCH XS, SCH 160, SCH XXS.

API 5L X65 pipe is also called ISO 3183 L450 pipe, it is a high level grade pipe in API 5L (ISO 3183) specifications, used for oil and gas transmissions. The reason we call it X65 pipe or L415 pipe is because it’s minimum yield strength required in 65000 Ksi or 450 Mpa.

API 5L has grades from B to X70 in common use pipelines, so Grade X65 pipe is one of the premium class material.

Same with other API 5L pipe, X65 pipe has two product specification levels of PSL1 and PSL2, and in some cases required for sour service use.

API 5L X65 Pipe Specifications

Though X65 pipe is a premium grade material, still it is carbon steel pipe not alloy pipe. It’s specifications and performances comply to carbon steel scope.

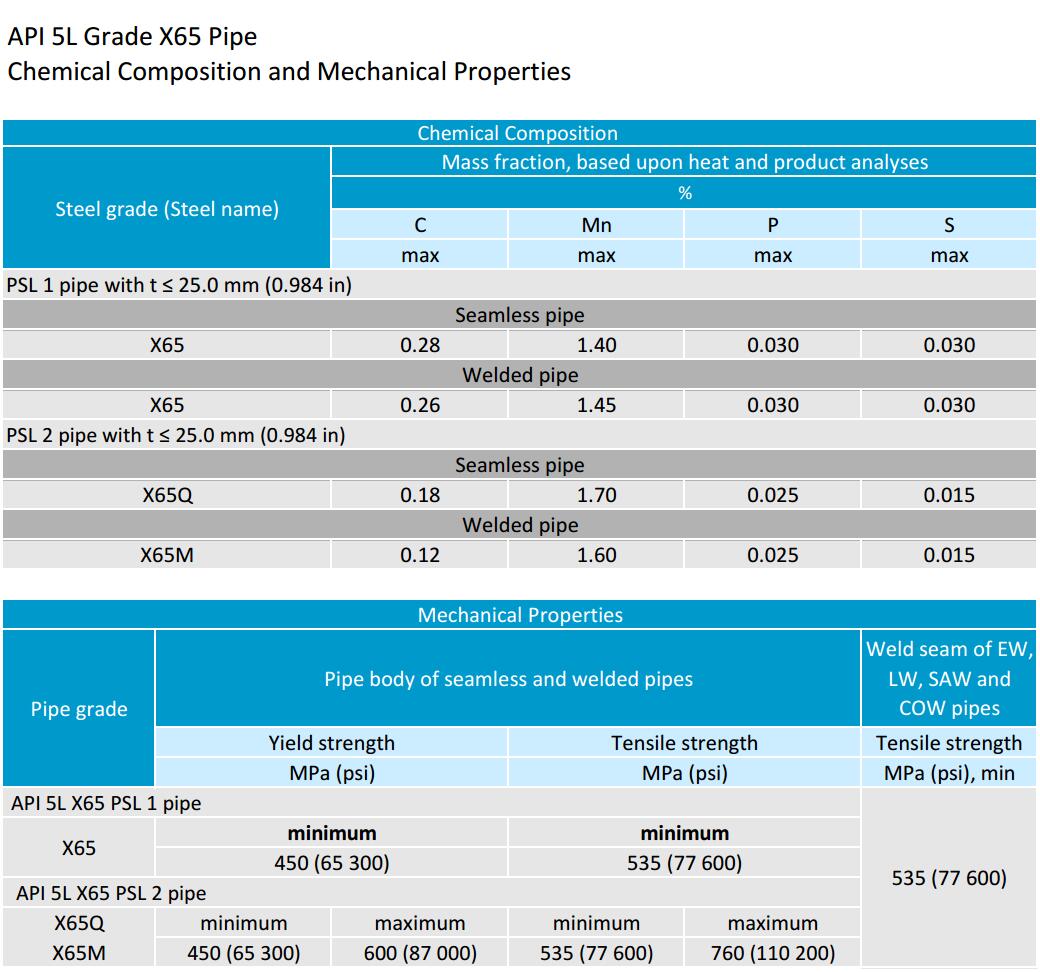

For X65 PSL1 and PSL2 types, chemical properties and mechanical strength as below:

API 5L X65 pipe for sour service use is more strictly than above two grades, so when refers to sour service pipe, it shall comply all of the PSL2 pipe requirements.

API 5L X65 Pipe Material Datasheet in PDF

API 5L Grade X65 PSL1, PSL2 and sour service pipe differences

API 5L X65 PSL1

API 5L Grade X65 or L450 PSL1 pipe is normal carbon steel material among the tree types and for common use, (None corrosion environment but in high pressure pipelines required a certain mechanical properties). so it has the highest content of C, Mn, Si, P, S than the other two types. (These chemical elements is lower the steel is purer). X65 PSL1 pipe Minimum yield strength is 450 Mpa (65300 psi), minimum tensile strength 535 Mpa (77600 psi).

API 5L X65 PSL2

For API 5L X65 PSL2 (API 5L X65Q.M or L450Q/M), C ≤ 0.18, Si ≤ 0.18, Mn ≤ 1.70, P ≤ 0.025, S ≤ 0.015, all of these elements have less value than PSL1. Since PSL2 requires CEq ≤ 0.43, and CEpcm ≤ 0.25. (Ceq is carbon equivalent, it affects the steel welding performances, strength value). And because of this, API 5L X65 PSL2 pipe (welded and seamless) mechanical strength has a maximum limits: yield strength 450 – 600 Mpa (65300 psi to 87000 psi), tensile strength 535 to 760 Mpa (77600 psi to 110200 psi)

API 5L X65 sour service

API 5L X65 PSL2 sour service pipe (X65QS/MS, L415QS/MS), C maximum is 0.10, Mn ≤ 1.45, Si ≤ 0.45, P ≤ 0.020, S ≤ 0.002, V ≤ 0.10, Nb ≤ 0.08, Ti ≤ 0.06, CEPcm ≤ 0.22. Sour service line pipe requires a strictly control on the chemical composition. So to protect pipe from corrosive environments like H2S, low carbon and low CEPcm value will reduce the martensite which sensitive to H bubble, so to improve the corrosive resistance to H2S. Moreover, P and S also should be less than normal line pipes. Out of these, the mechanical strength is the same with API 5L X65 PSL2 steel line pipes.

View how chemical composition affects to steel.

According to the data, 74% of pipeline accidents were caused from pipe corrosion, and H2S is the mainly corrosion types in corrosive environments. So it is very important to manufacture steel line pipe for sour service. View API 5L Pipe Specification for more details.

Octal provides API 5L X65 PSL2 Pipe for sour service, material also comply to NACE MR 0175.

Octal Supply Range for API 5L X65 pipe

Standard and Grades: API 5L X65

Product Specification Level: PSL1, PSL2

Material: NACE MR 0175 complied, for sour service

Working Environment: H2S corrosion

Manufacturing processes: Welded ERW, LSAW, SSAW, and Seamless

Sizes Range: 1” to 30”.

Common Sizes Applied: 2”, 3”, 4”, 6”, 8”, 10”, 12”, 14”, 16”, in SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, SCH XXS, etc.