API 5L X60 Pipe Specification

Brief Specification

Standard: API 5L / ISO 3183

Grade: X60, L450, PSL1, PSL2, SOUR SERVICE

Minimum Yiled Strength: 60,200 psi (415Mpa)

Outer Diameters: 1/2” to 100”

Thickness: SCH10, SCH 40, SCH STD, SCH80, SCH XS, SCH 160, SCH XXS etc

Length: SRL, SRL, 20FT, 40FT

Coating: 3PE/3LPE, FBE

API 5L X60 is a common high grade pipe material in API 5L specifciations for oil and gas transmissions. It’s also called L415 pipe, which named by yield strength minimum in 415 Mpa (60,200 psi). It covers manufacturing types in seamless (hot rolled and colde rolled), and welded in ERW, LSAW, SSAW (HSAW).

API 5L X60 pipe ranges in PSL1, PSL2, onshore/offshore, and sour service.

PSL1 is for common use material delivery conditions R As Rolled.

PSL2 specified with suffix letter N, Q, M, eg API 5L X60Q/M/N (Where sour services is described as API 5L X60QS/MS)

PSL2 is strict and higher than PSL1 on chemicals, mechanical properties and test requirements. View here differences between PSL1 and PSL2.

View other grades specification in API 5L Pipe.

Suffix Letter Means

R: As rolled

N: Normalizing rolled, Normalized formed, Normalized

Q: Tempered and quenched

M: Thermomechanical rolled or thermomechanical formed

S: Sour Service Use

Our Supply Range

Grade: API 5L X60 (Q, M, N, QS, MS), ISO 3183 L415.

Product Specification Level: PSL1, PSL2, NACE and Sour Service (API 5L X70MS/QS)

OD (Seamless): 1/2” – 40”, 21.3 mm – 1016 mm

OD Range (ERW): 21.3mm – 508mm, 1/2” – 20”

OD Range (LSAW): 406mm to

OD Range (SSAW/HSAW): up to 2500mm, 100”

Wall Thickness Schedule: Schedule 20, SCH 40, SCH STD, SCH XS, SCH 80, SCH 120, SCH XXS, SCH 160

Length: SRL (Single Random Length), DRL (Double Random Length), 20ft (6m), 40ft (12m),

Coating Finish Types: Black Painting, Oil Varnished, FBE, 3PE/3LPE, 3PP, Lined and Clad

API 5L X60 Pipe (L415 Pipe) Applications

X60 or L415 pipe used for the oil and gas transportation systems and petroleum industries. Market survey shows requirements quantity for API 5L X60 pipe is in big volume. (Which the other Grades X52 > X65 > X42 > X60 pipe, approved by the sales records from the Chinese manufacturers in 2019.)

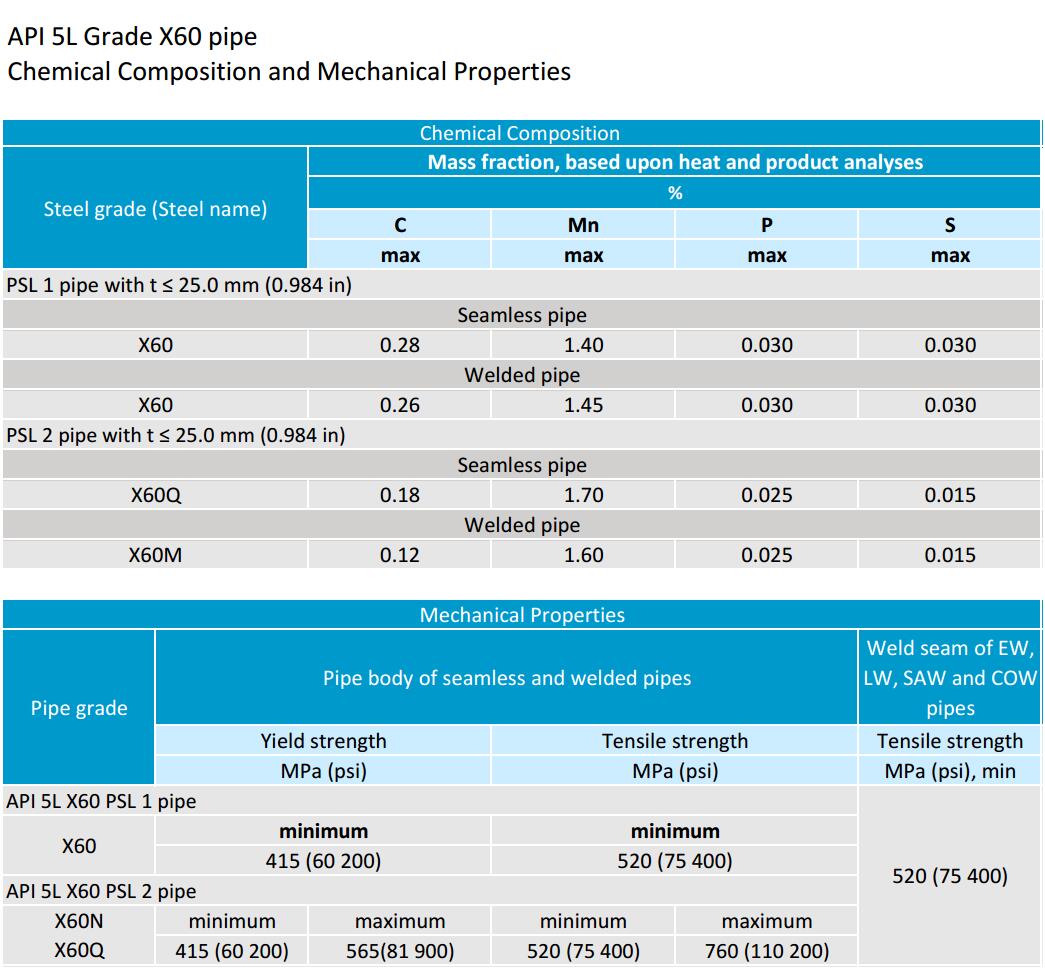

API 5L Grade X60 Pipe Specifications

API 5L X60 Pipe Data Sheet in PDF

Mechanical Strength

The performances of the API 5L X60 L415 is great. The tensile strength of the API 5L X60 L415 is minimum at 75400 Psi 520 Mpa, yield strength minimum 60,200 Psi 415 Mpa. It could bear big stress in oil and gas pipe systems.

The strength values are same for the seamless steel line pipe and welded steel line pipe including ERW, LSAW, SSAW.

On the other hand, X60 PSL 1 and PSL 2 the minimum strength values are no different but PSL2 limits the maximum strength value. According to API 5L 46th edition 2018.

Chemical Properties

The chemical property for API 5L X60 L415 the content is same with API 5L X46, X52, X56, X60, X65, X70.

In case of API 5L X60 PSL1 pipe welded types:

Maximum C ≤ 0.26%, Si ≤ 0.45, Mn ≤ 1.4%, P ≤ 0.030%, S ≤ 0.030%, Cu ≤ 0.50%, Nickel ≤ 0.50%, Cr ≤ 0.50%, Mo ≤ 0.15%, and the sum of the Nb, V, Ti shall be ≤ 0.06%. If the maximum content of the C reduce 0.01%, Mn will be increased 0.05% accordingly until to the maximum of 2.00% for API 5L Grade X60 PSL1 steel line pipes.

In case in PSL2 under maximum percentage:

C ≤ 0.12, Si ≤ 0.45, Mn ≤ 1.4, P ≤ 0.025, S ≤ 0.015, CEq ≤ 0.43, and CEp ≤ 0.25. Unless otherwise agreed, Cu, Ni, Cr, and Mo shall be less or equal to 0.50%. Nb + V + Ti ≤ 0.15%.

Our Advantages

Octal supplies API 5L X60 pipe for emergency requirements with stock in small quantity, with big quantity we can also coordinate to produce in the soonest time, and with coatings of FBE or 3PE.

Sample Description for Purchase of API 5L X60 Pipe

API 5L Grade X60 PSL1, welded LSAW, Carbon Steel, 30”, WT 0.375”, coated with 3PE in accordance of DIN 30670, Quantity 50 km, ends design Beveled, nominal length 12 meters.