API 5CT L80 Casing and Tubing Pipe Specification

Standards: API 5CT

Grades: L80-1, L80 9Cr, L80 13Cr, J55/K55, N80, P110

Production Specification Level: PSL1, PSL2, PSL3

Stock Available: Yes

Manufacturing process: Seamless, ERW (Optional only for L80-1)

Casing pipe dimension: 4-1/2” to 20”

Tubing dimension: 1.050” to 4-1/2”

Coupling thread: BTC, LTC, STC, EUE, NU, premium connections threads, HYD, and equivalent.

Length: R1, R2, R3

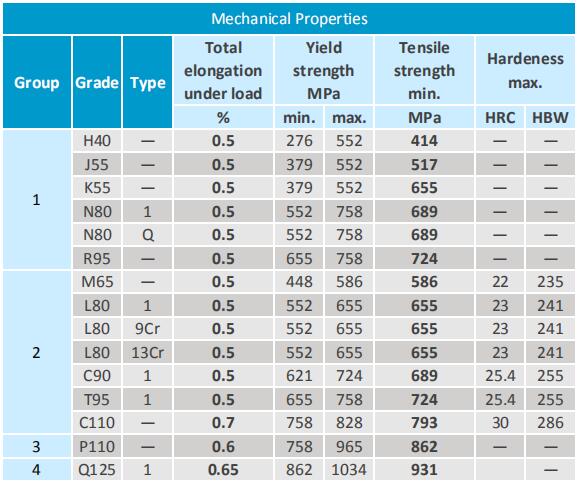

API 5CT L80 casing and tubing include grades L80-1, L80 9Cr (Cr 8%-10%), L80 13Cr (Cr 12%-14%), L80, minimum tensile strength 655 Mpa, yield strength 552 Mpa to 655 Mpa, it is a medium strength grade higher than J55/K55, and similar with N80 (YS 552 Mpa to 758 Mpa, TS 689 Mpa), L80 pipes has been used in oil well establishment, drilling and producinging oil and gas industries.

API 5CT Grade L80 includes L80-1, L80 13Cr, L80 9Cr

In this standard when the symbol L80 is used alone it covers Grades L80 Type 1, L80 9Cr (Chromium content 8% to 10%) and L80 13 Cr (Chromium content 12% to 14%).

API 5CT L80 13Cr Casing

L80 identification of color band

One red, one brown marked for L80-1. Pipe marked with L.

One red, one brown, two yellow marked for L80 9Cr. Simplified marking L9.

One red, one brown, one yellow marked for L80 13Cr. Simplified marking L13.

Special clearance couplings shall also have a black band.

Seal-ring coupling shall also have a blue band.

API 5CT Standard Scope

API 5CT standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

For pipes covered by this Standard, the sizes, masses and wall thicknesses as well as grades and applicable endfinishes are listed in API 5CT Tables C.1 and C.2 and Tables E.1 and E.2.

API 5CT L80 casing and tubing manufacturing types

L80-1 manufacturing types in seamless or welded EW and most generally made in seamless.

L80 9Cr, L80 13Cr only could be made in seamless.

Heat treatment methods for L80 pipes

Heat treatment is required for all L80 grade pipes.

L80-1 shall be heat treated with full-body, full-length, as per API 5CT 10th edition quenched and tempered (simplified with Q) shall be adopted to the products. L80 9Cr, L80 13Cr could be air-quenched.

Group 2

When requested by the purchaser, manufacturer shall produce evidence to show that the tempering practice will result in the pipe attaining the minimum tempering temperature.

Grade L80 13Cr may be subject to embrittlement when tempered below 620 ℃ (1150℉).

Reference Inspection for L80-1, L80 9Cr, L80 13Cr Casing and Tubing

Visual inspection for pipe surface

Dimension check

Mechanical test on tensile strength, yield strength and elongation

Chemical analysis

NDT test including Magnetic particle, Ultrasonic Test, Hydrostatic Test

Charpy impact test

Flattening tests

Hardness test

Drift test

Thread ends check with thread gauge and coupling check

None Destructive Test

For Grade N80Q, L80, R95 required full-body, full-length NDE of casing and tubing. All pipe shall be inspected for the detection of longitudinal imperfections on the outside and inside surfaces to accepted by level L4 by one or more of the following methods:

a) Ultrosonic testing in accordance with ISO 9303 or ASTM E213;

B) Flux leakage testing in acoordance with ISO 9402 or ASTM E570;

c) Eddy current concentric coil testing in accordance with ISO 9304 or ASTM E309;

d) For pipe outside surface, magnetic particle inspectoin in accordance with ISO 13665 or ASTM E709.

Bare steel thread protectors shall not be used on Grade L80 Types 9Cr and 13Cr Tubulars.

Surface Condition – Grades L80 9Cr and L80 13Cr

The internal surface of the pipe shall be free from scale after the final heat treatment.

Additional requirements for PSL-2 and PSL-3 products are specified in API 5CT Annex H.

API 5CT Grade L80 Casing Pipe:

As we know steel casing pipe is considered as a pipe pile that will stabilize the oil well. L80 Casing is installed in oil well downhole to provide structural integrity to the wellbore and bear external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It needs to take pressure from its own weight and withstand the torque and transaxial pressure placed on it while running downhole.

API 5CT L80 Tubing:

L80 Tubing placed inside the casing used to transport crude oil or natural gas from the source rock to the ground wellhead. Inside tubing is sucker rods, which used for pumping oil and gas.

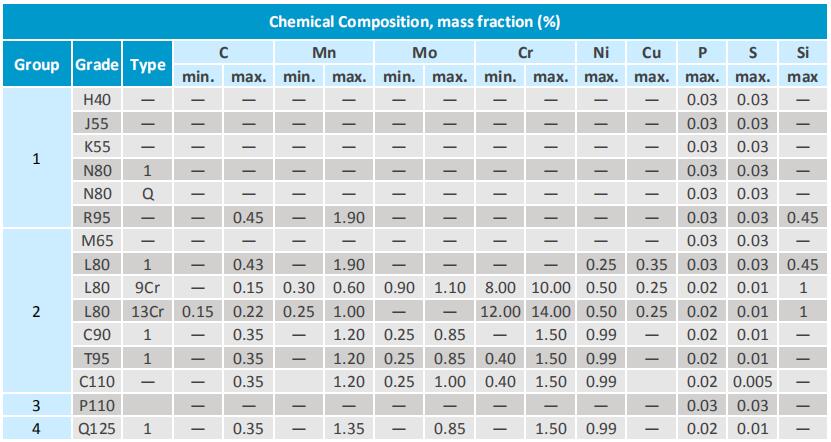

Chemical Composition

The carbon content for L80 may be increased up to 0,50 % maximum if the product is oil-quenched.

Mechanical Properties

Connection type, ends and Couplings

Casing and tubing ends type are different where for casing usually BTC and tubing with EUE or NU, threads comply with API 5B.

L80 tubing connections with regulare and special clearance

EUE: External upset, tubing ends have an exeternal upset with a larger diameter and thickness than tubing body

NU: Non upset, tubing ends same diameter and thickness with tubing body

L80 casing pipe connection types

Common use connection BTC, buttress thread marked with BC

LC: Long round thread

SC: Short round thread

Premium connections like HYD, and other gas tight thread

Customized connection threads as per client requirement

Dimension and tolerances

Length Range:

R1: 4.88 to 7.62 meters, permissible variation max 1.83 meters, and permissible length min 5.49 meters.

R2: 7.62 to 10.36 meters.

R3: 10.36 to 14.63 meters.

Outer diameter tolerance:

For pipes below 4-1/2 inch, tolerances +/- 0.79mm or 0.031 inch

For pipes equal and above 4-1/2 inch, tolerances +1% and -0.5% of pipe diameter

Wall thickness tolerance – 12.5%.

Imperfections:

Maximum permissible depth of linear imperfections, external and internal imperfections 12.5 of wall thickness. In case required 5% also could be adopted for P110 grade.

Octal supply range for P110 casing and tubing

Standards: API SPEC 5CT L80-1, L80 9Cr, L80 13Cr Casing and Tubing

Grades: L80-1, L80 9Cr, L80 13Cr

PSL level: PSL1, PSL2, PSL3

Stock Available: Yes

Manufacturing process: Seamless, ERW (ERW Option ony for L80-1, not applied to L80 9Cr or L80 13Cr)

P110 Casing and Tubing Outer Diameter: 2-3/8”, 2-7/8”, 3-1/2”, 4-1/2”, 5-1/2”, 6-5/8”, 7”, 7-5/8”, 7-3/4”, 8-5/8”, 9-5/8”, 10-3/4”, 11-3/4”, 13-3/8”, 16”, 18-5/8”, 20”

Thickness: 4 LB/FT to 106.59 LB/FT, 0.244” to 0.875”

Coupling thread: BTC, Buttress (Regular, Special bevel or special clearance), LTC, STC, premium connections threads.

Length: R1, R2, R3, customized