API 11B Sucker Rod, Pony Rod, Drive Rod for Sale

Octal has API 11B sucker rods for sale in below grade and dimensions.

Outer Diameters: 5/8” to 1 3/4”.

Grades: C, K, D, KD, HL, HY.

Material: AISI 4130M, AISI 4138M, AISI 4330M, AISI 4142M, AISI 8630

Sucker Rods Length: 25 ft or 30 ft

Pony Rods Length: 2 ft to 10 ft.

Ends Type: Class T coupling, Reduced Diameter, SM coupling.

Rods Type: Sucker Rods, Pony Rods, Polished Rods, Sinker Bar, Drive Sucker Rod, Centralized Sucker Rod, Anti-Twist Sucker Rod

sucker rod is a long, slender rod used in the oil and gas industry, primarily in pumping systems for extracting oil from wells. It connects the surface pumping unit to the downhole pump, transferring the mechanical energy needed to lift the oil to the surface. Sucker rods are typically made of steel and are designed to withstand the harsh conditions of the well environment, including high pressures and corrosive fluids.

Octal has high strength API 11B sucker rod for sale in Grade C, K, D, KD, HL, HY. Material available in alloy steel AISI 4130M, AISI 4138M, AISI 4330M, AISI 4142M, AISI 8630, with high strength and anti-torsion performances. API 11B specification includes the technical requirements for Sucker Rod, Pony Rod, Drive Rod, Polished Rod, Sinker Bar.

Sucker Rod Specifications / Common Features

Construction

Sucker rods are typically made of high-quality carbon or alloy steel to withstand the high tensile and compressive forces encountered during drilling and production operations. They are manufactured in various grades and sizes to suit different well conditions.

Length and Diameter

Sucker rods are typically available in lengths ranging from 25 to 30 feet (7.6 to 9.1 meters). The diameter of the rods can vary, but common sizes range from 5/8 inch to 1-1/4 inches (15.9 to 31.8 millimeters).

Types

There are different types of sucker rods available, including conventional sucker rods, hollow sucker rods, and continuous sucker rods. Conventional sucker rods are solid, while hollow sucker rods have a hollow central section to allow fluid flow. Continuous sucker rods are made from one continuous piece of steel without any threaded connections.

Function

Sucker rods are used to transmit mechanical power from the surface to downhole pumping equipment. They are connected to a pumping unit, such as a pumpjack, which reciprocates the rods up and down to create the necessary pumping action. This action helps lift the oil or gas to the surface.

Pumping Mechanism: In a typical setup, the sucker rod is attached to a pump at the bottom of the well, and as the surface unit operates, it moves the rod up and down, creating a suction effect that draws oil into the pump and up to the surface.

Threaded Connections

Sucker rods have threaded connections on each end, allowing them to be joined together to form a continuous string. The connections are usually made using a coupling or a rod clamp, ensuring a secure and leak-free connection.

Corrosion Protection

Sucker rods are susceptible to corrosion due to exposure to well fluids and harsh downhole conditions. To protect against corrosion, the rods are often coated with protective coatings or treated with corrosion inhibitors.

Maintenance and Inspection

Regular maintenance and inspection of sucker rods are essential to identify any signs of wear, corrosion, or damage. Damaged rods should be replaced promptly to ensure safe and efficient well operations.

Materials

Sucker rods material made of carbon or alloy steel. Alloy Steels refer to AISI 4130M, AISI 4138M, AISI 4330M, AISI 4142M, AISI 8630M, etc.

Sucker Rods Coupling Types

with the connection T coupling or reduced diameter coupling. sucker rod connect each other and extended to an under ground piston of the reserve oil, by the reciprocating motion to pump the oil.

Overall, sucker rods play a crucial role in the oil and gas industry, providing the mechanical power necessary for the extraction of oil and gas from underground reservoirs.

Pony Rod

Pony rod is short sucker rod that usually length under 10ft, application is similar with sucker rod for oil pumping, as some parts will need short pieces to complete the oil well drilling.

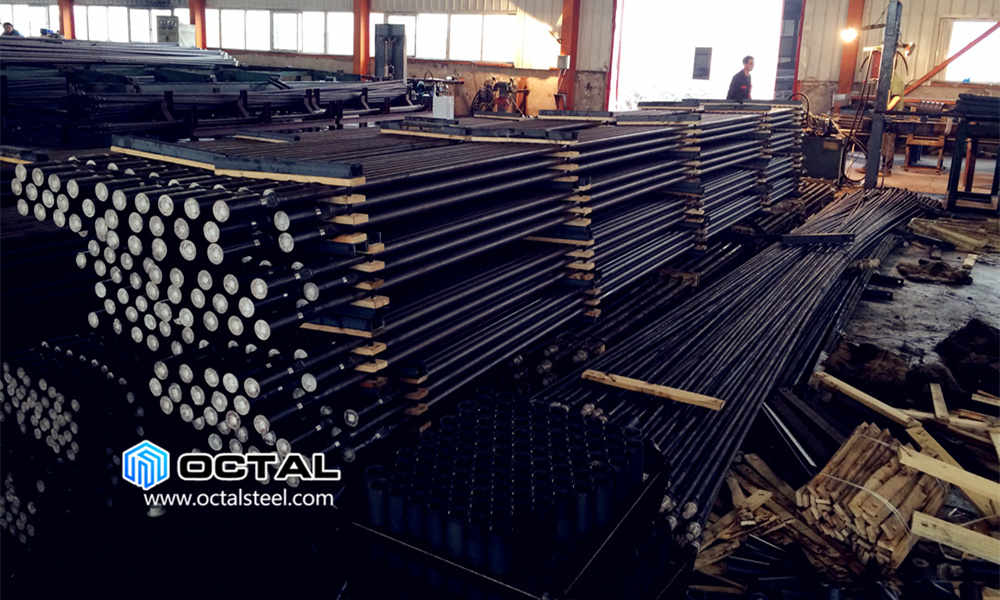

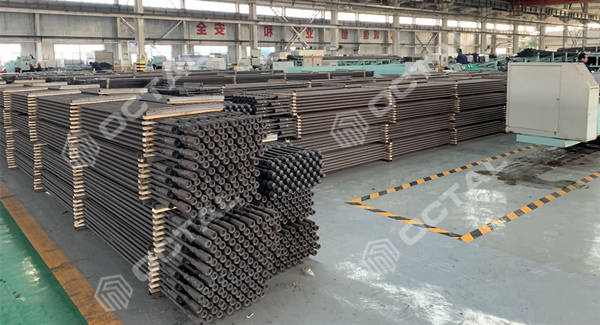

Sucker Rod Manufacturing Processes

Manufacturing Processes of the API 11B Sucker Rod

Rod Test – Straightening – Non-Destructive Inpection – Friction welding – Heating – Thermal Straightening – Impeller Blasting – Ends Threading – Assembly – Anti-Corrosion – Packing – Warehousing

Sucker Rod Raw Material

Dimensions and Grades of sucker rods for Sale

API 11B sucker rod for sale in below grade and dimensions.

Outer Diameters:5/8 in, 3/4 in , 7/8 in, 1 in, 1 1/8 in, 1 1/4 in, 1 1/2 in, 1 3/4”.

Length: 25 ft or 30 ft

Pony Rods Length: 2 ft, 4 ft, 6 ft, 8 ft, 10 ft and customized.

Ends Type: Class T coupling, Reduced Diameter, SM coupling.

Thread: PIN X BOX, PIN X PIN

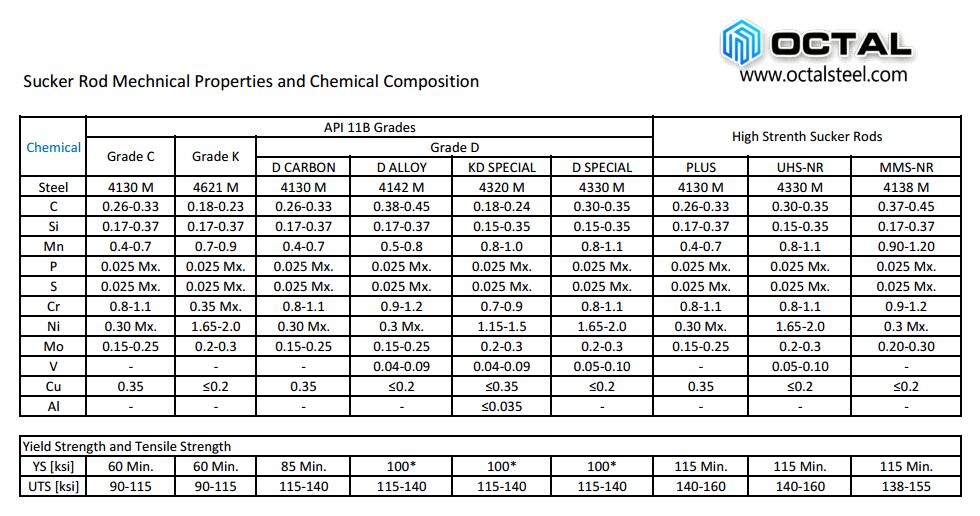

Sucker Rod material chemical and strength

Sucker Rods Grade C, D, K steel materials including ANSI 41XX (4138M, 4330M, 4142M etc) chemical composition and mechanical properties.

API 11B Sucker Rods Standard Specification

Please note above values are for references, in case specific order, manufacturer maintain the reservation to modify it.

API 11B sucker rod grades in C, K, D, mechanical properties as below:

a. Grade C sucker rod minimum and maximum tensile strengths of 90,000 and 115,000 psi, respectively.

b. Grade K: 90,000 psi to 115,000 psi. These rods are made with 1.65 to 2.00% nickel alloy, therefore, it is more expensive than Grade C but has improved corrosion-related properties.

c. API 11B Grade D sucker rod tensile strength minimum 115,000 psi and maximum 140,000 psi. Grade D covers three types of material: Carbon steel, alloy steel, and special-alloy steel.

Applications for different grades

As we know in API 11B there are Grade C, K, D, more over there are high strength sucker rods with Standard SY/T5029-2006 covers grades in KD, HL, HY; KH level rod will be complied with manufacturer internal protocols.

Below applications for each grades:

1. Grade C sucker rod is mainly used for light, medium load, no corrosion or corrosion shallow Wells or in deep well pumping, material is carbon steel or manganese steel.

2. Grade D sucker rod is made of high quality alloy steel, after heat treatment with high strength, plasticity is good, long life and other characteristics, it is suitable for light when there is no corrosion or corrosive medium in the deep Wells under the environment of use.

3. Grade H(HL and HY) sucker rod is made of high quality alloy steel manufacturing, have the characteristics of ultra high strength, used in deep well, big strong pump used in production.

4. K and KD sucker rod with different content of Ni Cr – Ni – Mo high quality alloy steel manufacturing, have anti-corrosive, resistance to corrosion function, respectively applicable to strong corrosion of shallow, middle and deep Wells.

API 11B Sucker Rods for sale in various types

Mainly there are below types for sale:

Special Sucker Rods: Hollow sucker rod, polished rod

Continuous rod: Threaded, socket sucker rod

Drive Sucker Rod

Sinker Bar

Centralized Sucker Rod

Anti-Twist Sucker Rod

Recent Comments