Differences between 3PE (3LPE Coated Pipe) and FBE Epoxy Coating Pipe

When people purchase steel pipe for pipeline systems, always we see the pipe has been asked for a epoxy coating like 3PE (3LPE) or FBE.

So how much do you know about epoxy coated (3LPE/3PE or FBE) pipe? And in which cases it shall be used? How much of the cost the the 3PE, FBE coating layers?

Here is the answers to be briefly:

FBE pipe is coated with Epoxy Coatings, it could be used for internal and exernal coating, and mostly used pipe internal coating. Specified as Fusion Bonded Epoxy pipe.

3LPE pipe coated with Epoxy inside, adhesive layer middle, and outside with polyethylene layer. 3LPE will be only used for pipe external coating 3LPE.

3LPE/FBE coated pipe application

3PE/3LPE coated pipe and FBE Epoxy coating/coated steel pipe are widely used in pipeline systems for the transmission of oil, gas, water and other fluids. They have highly resistance to corrosive from chemicals, moisture, harmful environment etc.

What kind of pipes could be coated with 3LPE/3PE or FBE

Almost all kind of steel pipes could be coated with FBE or 3LPE. such as

Stainless steel pipe

ASTM A312, ASTM A269 stainless pipe

Carbon steel pipe

API 5L line pipe from Grade B to Grade 80

ASTM A53 pipe (Hot dipped galvanized steel pipe)

ASTM A106 pipe

ASTM A252 pipe

ASTM A134 and A135

ASTM A333

Alloy steel pipe

ASTM A335

Nickel Alloy pipes

CRA clad or lined pipe

What is FBE (Fusion Bonded Epoxy) coating steel pipe?

FBE coating pipe is Fusion Bonded Epoxy coating steel pipe. It could be applied for external or internal coating, with heat resin for pipe. With coated a form of dry powder at thickness 400-600 microns on to the heated surface of pipe. Once the FBE coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the pipe surface. The FBE layer in a even form and have good resistance to the chemical reaction.

FBE Epoxy coated pipe Features

The advantage of the FBE coating pipe is convenient to spraying, no pollution, excellent resistance for high-temperature (-40°C to 85°C);

High strength and anti-bending performances;

Strong adhesion, good integrity, anti soil stress and wear.

FBE coated steel pipe usually buried in soil and under water between -40~85°C temperature.

On the other hand, the defect of the FBE pipe is it doesn’t have good resistance to mechanical performances and humid conditions.

How many types for the FBE Epoxy coated pipe?

It developed from 1950s, and industrialization in 1960s. FBE pipe have two kinds: One layer and two layers pipe. FBE Dual layers coated pipe is recommended to applied for the offshore pipelines and the pipelines systems that operated in the tough environments, it provides high performances on the impact resistance and flexibility. Offers suitable protection for the coating from the damage during transportation and construction.

While FBE single layer coated pipe is the generally type for the FBE coated pipe. It offers a rough, non-slip surface for a pipeline that need concrete coating. A special fusion bonded epoxy powder mixed with solid epoxy resin and other adhesive material that helped to adhere to pipe surface.

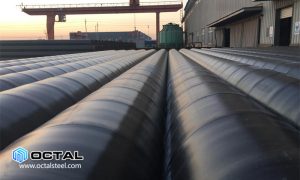

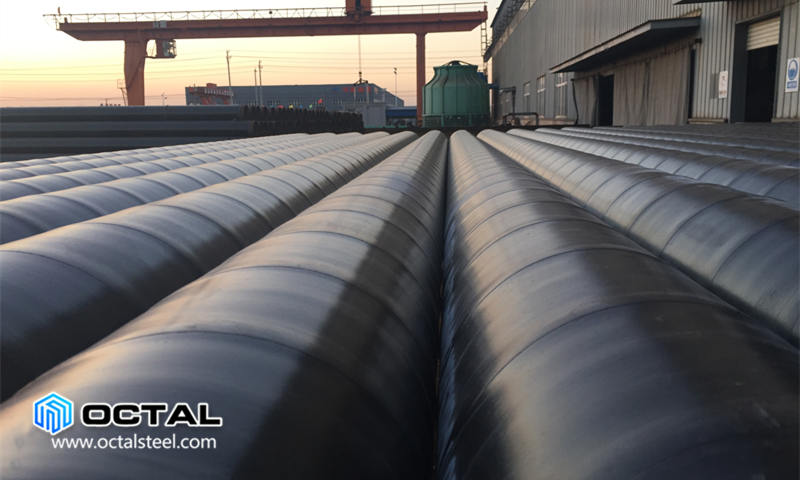

What is 3LPE Coated pipe?

The 3LPE coated pipe inlcudes 3 layer coatings, first FBE coating, middle is adhesive layer, outside polyethylene layer. 3PE coating pipe is another new product developed on the FBE coating basis since 1980s, which contains adhesives and PE(polyethylene) layers. 3PE can strengthen the pipeline’s mechanical properties, high electrical resistance, waterproof, wearable, anti-aging.

It could protect pipe from the heat loss which only account for 1/4 of pipe.

3LPE coated pipe include 3 layers:

For The first layers is fusion bonded epoxy, which thickness is larger than 100μm. (FBE>100μm)

The second layer is adhesive, which effect is binding epoxy and PE layers. (AD: 170~250μm)

The third layers is PE layers which is polyethylene have advantages to anti-water, electrical resistance and anti mechanical damage. (φ300-φ1020mm)

Therefore, 3PE coating pipe integrated with the advantages of FBE and the PE. Whichg more and more widely used in buried pipeline’s transporting of water, gas and oil.

In case manufacturing equipment, 3PE coating steel pipe manufacturers they can also do FBE coating pipe.

3PE/3LPE coated pipe features and advantages

3LPE coated pipe mostly used for external coating for corrosion resistance against outside environment, FBE is for pipe internal coating to against fluid corrosion, used for chemical industry or for transimission of the drinkable water.

Durable lifetime

3LPE coated steel pipe have good stability and anti-aging performances under the normal work temperature and pressure conditions, consequently its lifetime can prolong above 50 years.

Corrosion resistance

Due to PE elements structure stability is very high, it is resistant to corrosion of natural gas, liquefied petroleum gas, artificial gas and other chemical subjects, no need secondary anti-corrosion equipment. The chemical of soil does not produce any effects to the pipe.

Flexibility

3PE/3LPE is a kind of soft and flexible material, it can prolong 5 times length then break. While it is easily to bend and no damage. 3LPE/3PE coating steel pipe can bypass objects and cut the fees of installation.

Good resistance of impact and earthquake

Polyethylene is not fragile under low temperature, there for, it is safe used in the temperature at the range of -60℃~60℃. So it can adapt to going down of pipeline, Work in winter. Due to good impact performances, PE pipeline won’t easily to break.

Excellent wear resistance

Experiments shows that PE pipe wear resistance is 4 times of pipe. especially in area of transporting mud. Compared to varnished pipe, PE coated pipe have better wear resistance.

3PE/3LPE have smooth surface, its manning coefficient is 0.009. Because of smooth internal surface and non-sticking performance, 3PE/3LPE coated steel pipe shows higher ability for transporting, and reduce the loss of pressure and water transporting. Low water permeation characteristic provides improved isolation from sea water compared to the other coating systems and FBE pipe.

Good environment protection performance

3LPE coated steel pipelines in manufacturing process won’t add heavy metal stabilizer, the PE material have no poison and harm, is a kind of green material, and itself can recycled will not cause pollution to the environment.

Excellent electric resistance, anti-static performances.

These properties make PE pipeline suitable for flammable and explosive conditions.

Safe and reliable connection way

3LPE/3PE coating steel pipe mainly use hot melt and fused connection, keep the interface and pipeline connect as a whole. There is no water and gas leakage.

Light, easily to move, and convenient for construction

3LPE layers weight only account 1/8 for steel pipe, easily to move, bend, welding process is convenient and fast, lower fees for whole project, obvious economic benefits.

Since 3LPE and FBE coating can prolong the lifetime of same steel pipe from several years to decades years, it’s required more than more in recent year pipeline projects.As a result of steel pipe corrosion, the whole world suffers average loss about 3% of global GDP per year, about 2.2 trillion dollars in 2015 according newest data. In which, oil, gas and petroleum industry loss account for 45% about 1 trillion dollars in 2015. According by data, more than 70% oilfield has explored easily to corrupt. For example, The US loss has rise up to 26% of direct economic loss , and China account for 10%.

Octal can provie 3LPE coated pipe or FBE coated pipe with different standard and types, please do not hesitate to contact us for an offer if you have such requirement.