ASTM A213 T11 Tubing Specification

Standard: ASTM A213/ASME SA213 for alloy and stainless steel tubing and pipe

Grade: T9, T11, T22, T91, T92, TP304/L, TP316/L, TP317/L, TP321/H, etc.

OD: 1/8” to 16”. 3.2mm to 406mm

WT: 0.015” to 0.500”, 0.4mm to 12.7mm

Length: 10ft, 20ft, 40ft, or customized length

ASTM A213 T11 tubing (ASME SA213 T11 tubing) is composed of Chrome Moly Alloy material and is widely used in high-temperature applications, especially in boilers and superheaters. Given its critical applications, this type of pipe is typically priced significantly higher than standard carbon pipes.

Common grades in ASTM A213 Standard

Common grades include T9, T11, T12, T21, T22, T91, as well as stainless grades such as TP304/L or TP316/L.

ASTM A213 Standard Scope

According to ASTM specifications, this particular specification pertains to seamless ferritic and austenitic steel tubes for use in boilers, superheaters, and heat exchangers. The specific grades covered by this specification include T5, TP304, and others listed in Tables 1 and 2.

The tubing size ranges from an internal diameter of 1/8 inch up to an outer diameter of 5 inches, with thicknesses ranging from 0.015 to 0.500 inches (0.4 mm to 12.7 mm). If other sizes are required, they can be specified as part of the order, along with minimum and average thicknesses.

You can refer to the ASTM A213 standard specification.

Manufacture and Condition

The tube material is typically composed of alloy steel or stainless steel, and is manufactured through seamless hot rolling or cold drawing techniques.

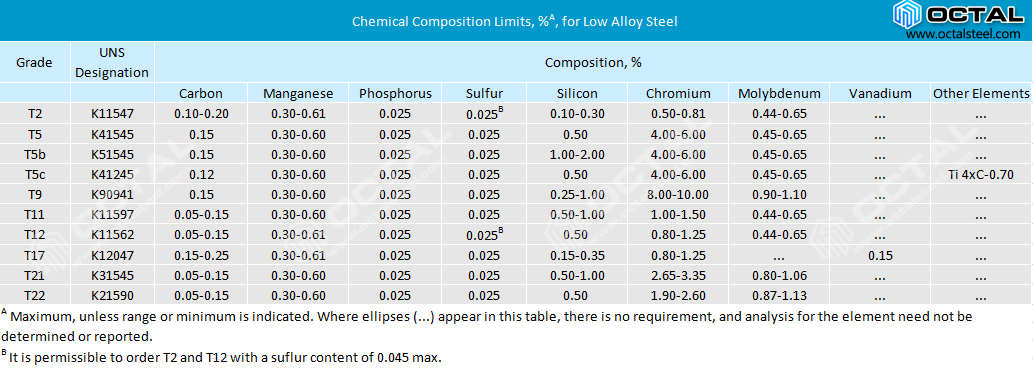

Chemical Composition

Table 1

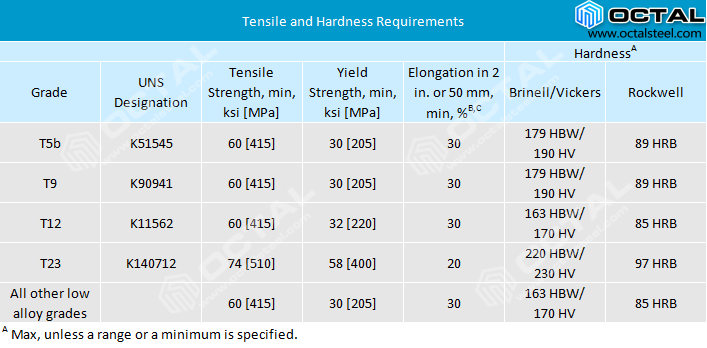

Tensile Strength and Hardness Strength

Table 2

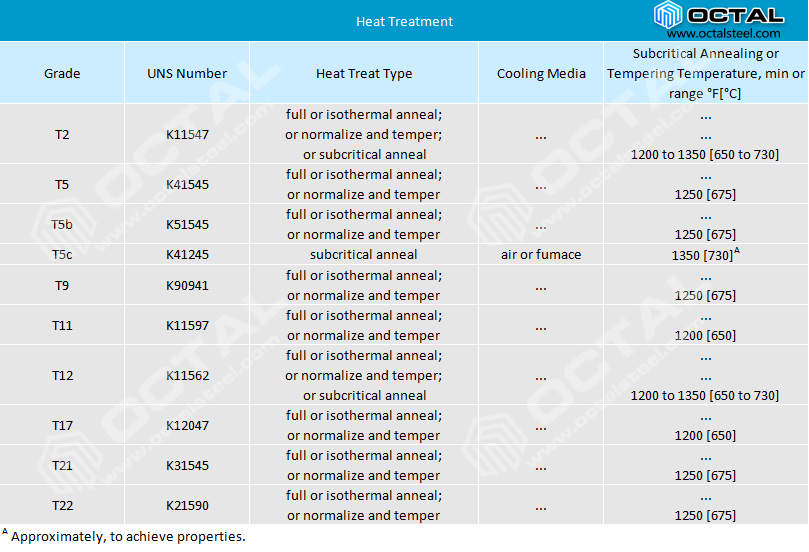

Heat treatment

The ferritic alloy and ferritic stainless steel shall be reheated for heat treatment in accordance with the requirements of Table 3. Heat treatment shall be carried out separately and in addition to heating for hot forming.

Table 3

If any controlled structural characteristics are required, these shall be specified in order so as to be a guide to the most suitable heat treatment.

Related Standard for Producing ASTM A213 pipe

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferro alloys

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

Ell2 Test Methods for Determining Average Grain Size

A5.5/A5.5M Specification for Low-Alloy Steel Electrodes for Shielded Metal Arc Welding

A5.23/A5.23M Specification for Low-Alloy Steel Electrodes and Fluxes for Submerged Arc Welding

A5.28/A5.28M Specification for Low-Alloy Steel Electrodes for Gas Shielded Arc Welding

A5.29/A5.29M Low-Alloy Steel Electrodes for Flux Cored Arc Welding

Flattening Test

One flattening test shall be made on specimens from each end of one finished tube, not the one used for the flaring test, from each lot.

Flaring Test

One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test,

from each lot.

Hydrostatic or Nondestructive Electric Test

Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the option of

the manufacturer, unless otherwise specified in the purchase order

Heat treatment types for common grades

a. Grades T9, T11, and T22 are subjected to heat treatment methods such as full or isothermal annealing, normalization, and tempering. When opting for the tempering process, the tempering temperature for T9 and T22 must be above 675℃, while T11 must be above 650℃.

b. Grades T91 and T92 are required to undergo normalization and tempering, with the normalizing temperature being above 1040℃ and the tempering temperature being above 730℃. These conditions apply during delivery.

Tolerances

Permissible variations from the specified minimum wall thickness shall be in accordance with Specification A1016/A1016M.

For Hot Formed Tubes

A: t = specified wall thickness D = specified outside diameter

For Cold Formed Tubing

For cold formed tubes, permissible variations from the specified average wall thickness shall be within +/- 10% of the specified average wall thickness. For hot formed tubes, unless otherwise specified by the purchaser, permissible variations shall comply with the table provided above.

Octal supply range for ASTM A213 T11 Tubing

Standard: ASTM A213/ASME SA213 for alloy and stainless steel tube and pipe

Grade: T9, T11, T22, T91, T92, TP304/L, TP316/L, TP317/L, TP321/H etc

OD: 1/8” to 16”. 3.2mm to 406mm

WT: 0.015” to 0.500”, 0.4mm to 12.7mm

Length: 10ft, 20ft, 40ft, or customized length