ASTM A709 Grade 50 Steel Plate Specification

Standard: ASTM A709

Grades: 36, 50, 50S, 50W, HPS 50W, HPS 70W, and HPS 100W

Thickness Range: 6 – 100 mm

Width Range: 900 – 4800 mm

Length Range: 3000 – 12000 mm

Steel Cutting Services: Flame Cutting Steel, Laser Cut Steel, Waterjet cutting steel sheet, Plasma Cutting.

ASTM A709 Grade 50 steel plate applies to carbon steel and high-strength low-alloy structural steel for bridges, steel plates, bars, and quenched and tempered alloy steel structural steel plates.

How many grades are there in ASTM A709 standard

There is a total of 7 grades in this standard, Grade 36, 50, 50S, 50W, HPS 50W, HPS 70W, and HPS 100W.

Related Standard for Producing ASTM A709 Steel Plate

Referred ASTM Documents:

A6/A6M The standard for the common requirements for rolled structural steel bars, plates, shapes, and sheet piling.

A36/A36M The standard for carbon structural steel.

A370 The standard for the test plan and definitions for mechanical testing of steel products.

A572/A572M The standard for high-strength low-alloy columbium-vanadium structural steel.

A588/A588M The standard for high-strength low-alloy structural steel, up to 50 ksi [345 MPa] minimum yield point, with atmospheric corrosion resistance.

A673/A673M The standard for sampling procedure for impact testing of structural steel.

A992/A992M The standard for structural steel shapes.

G101 Guide for estimating the atmospheric corrosion resistance of low-alloy steels.

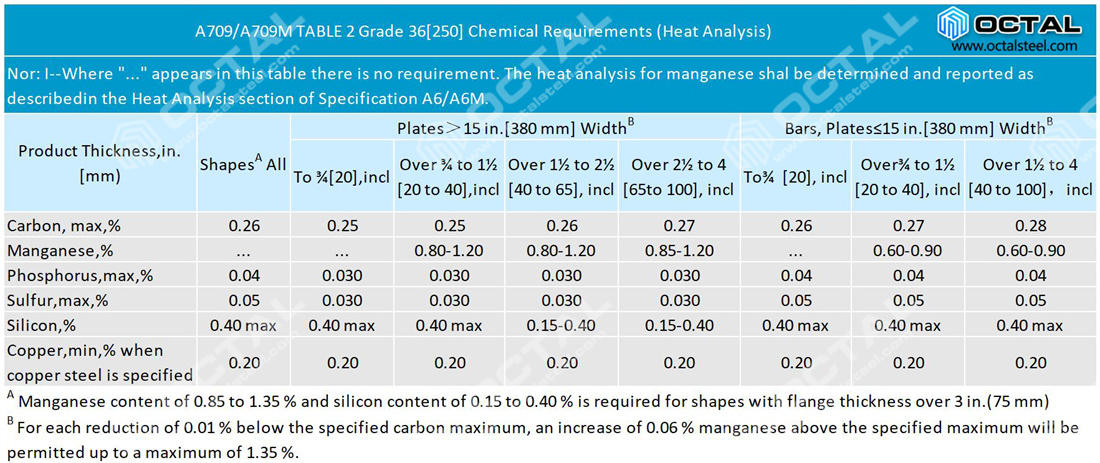

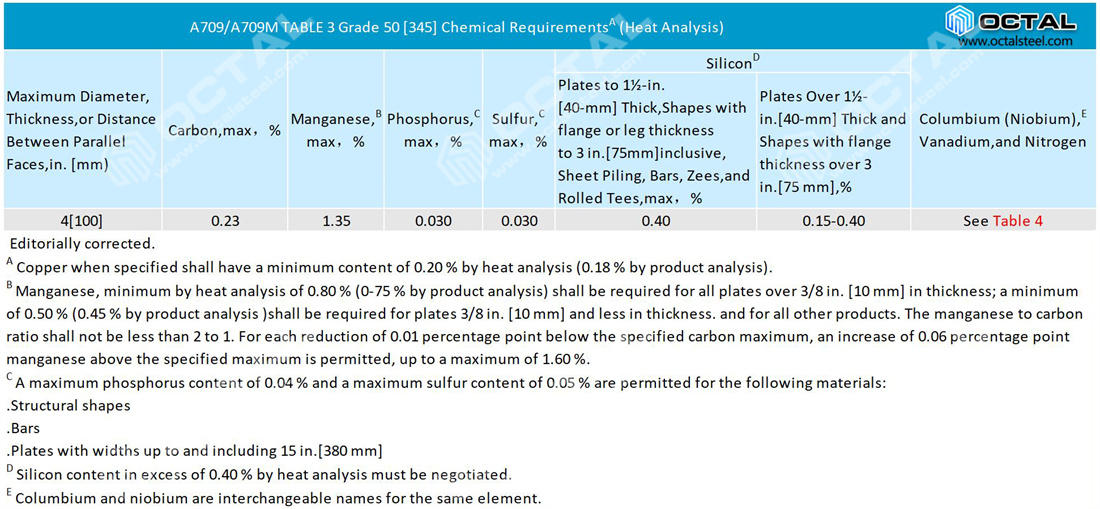

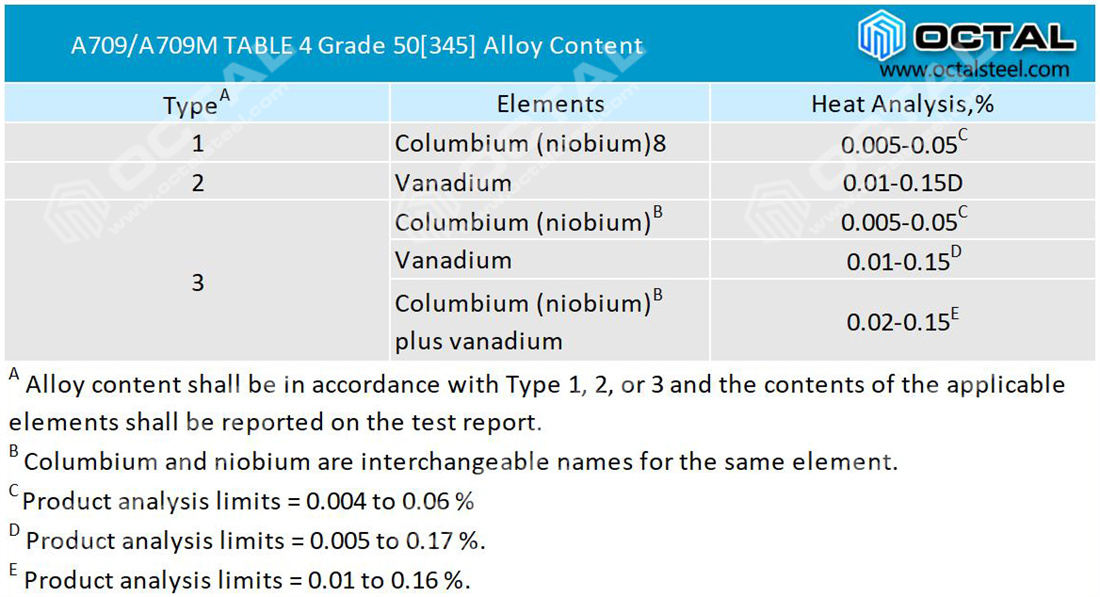

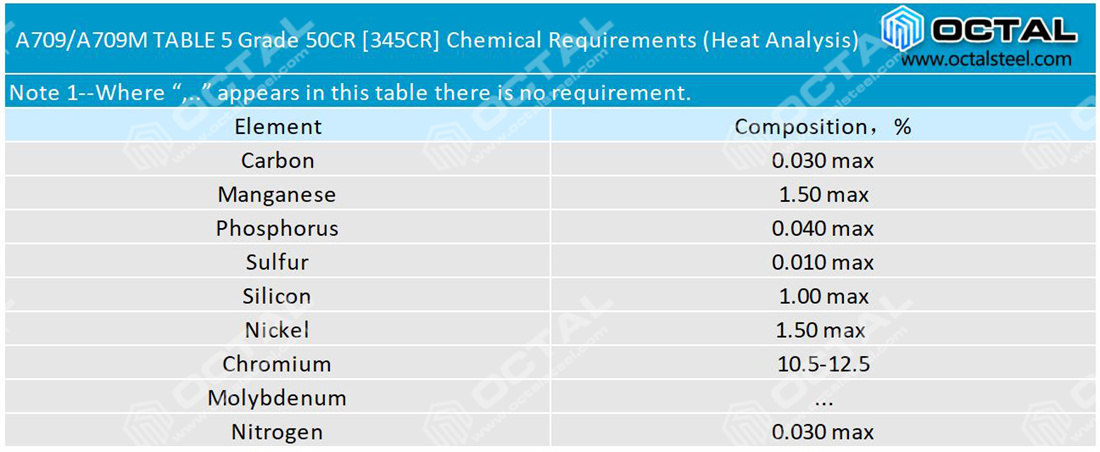

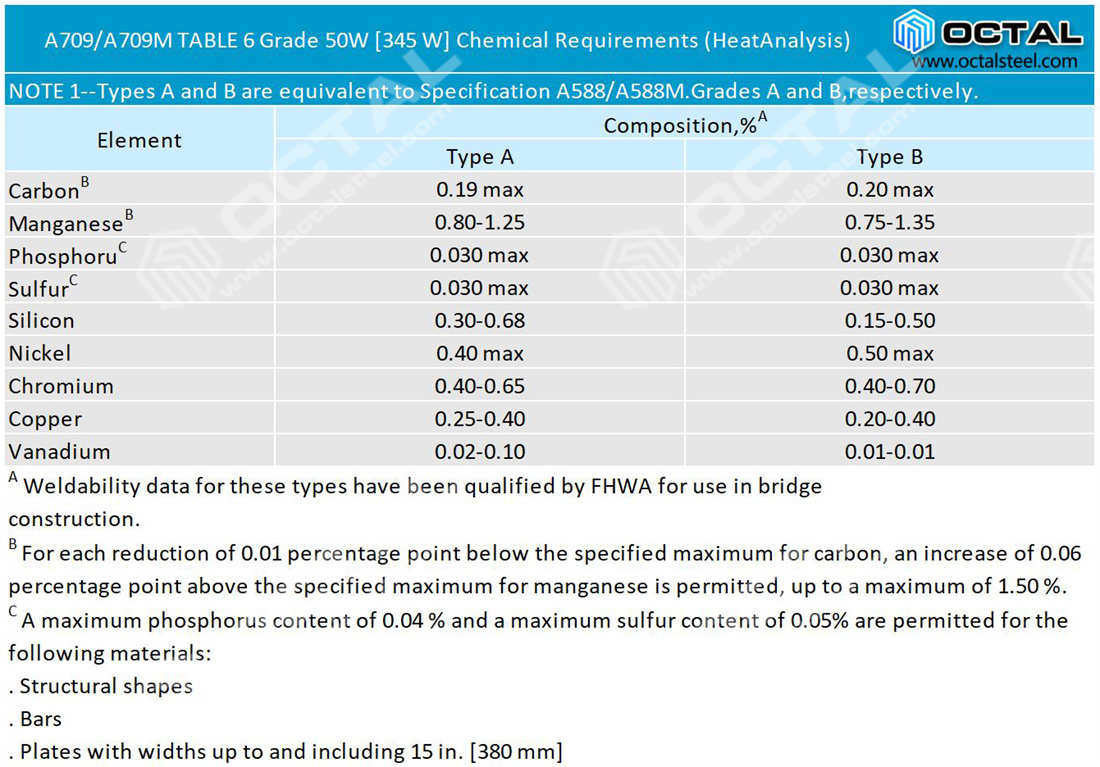

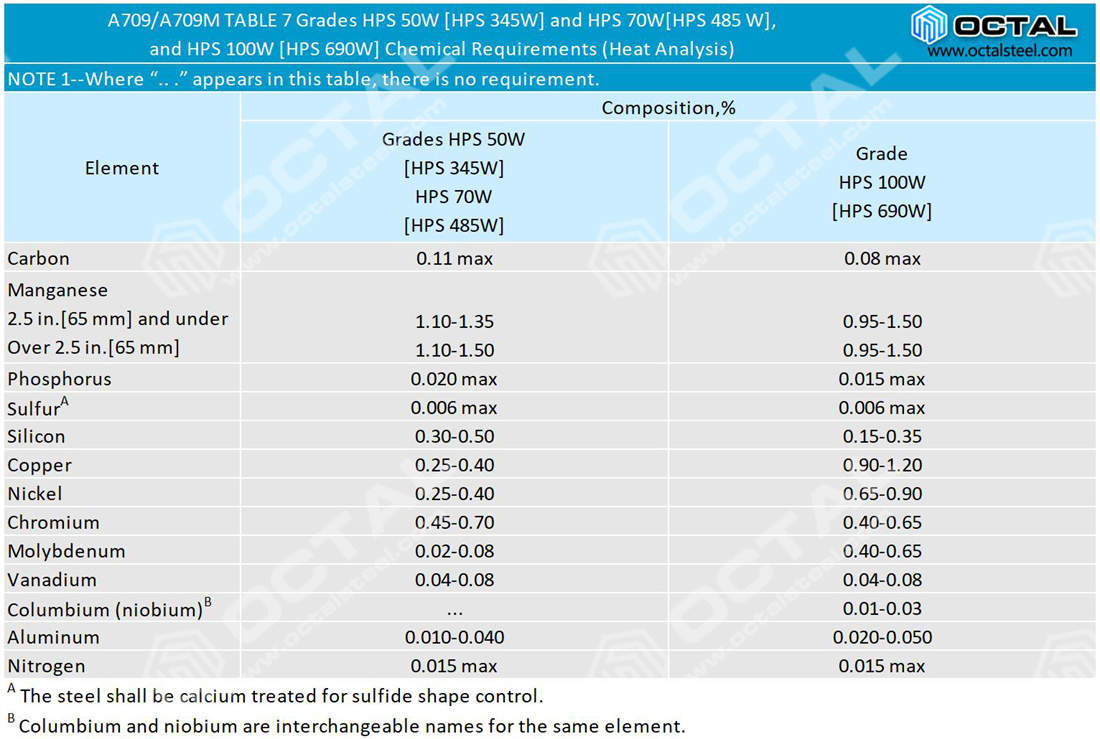

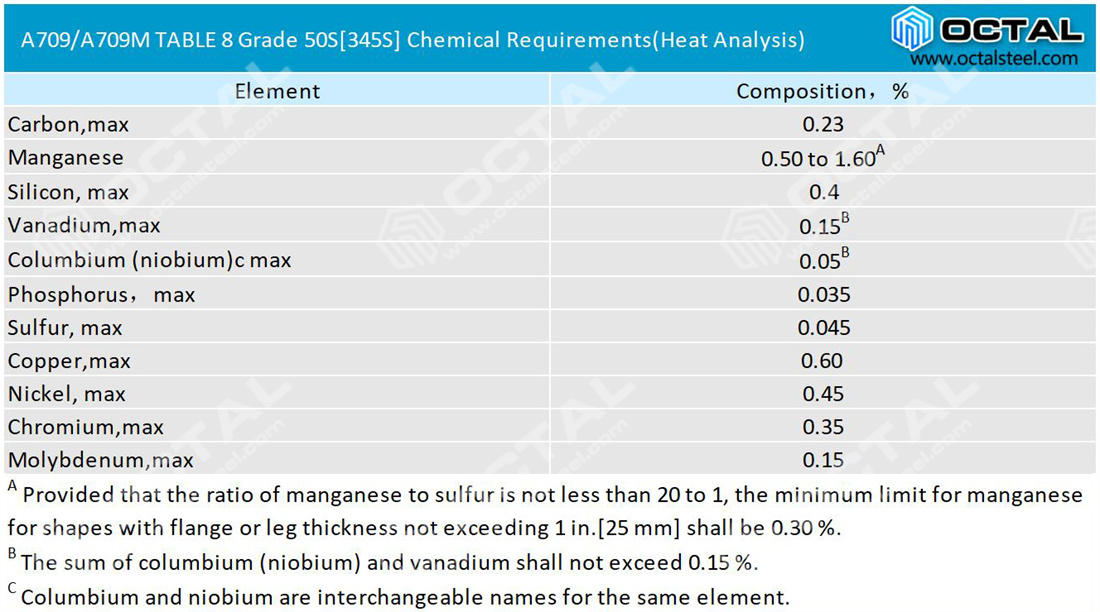

ASTM A709 Chemical Composition

There are differences in chemical composition as shown in the following tables:

For Grade 50S [345S], in addition to the elements listed in Table 8, test reports shall include, for information, the chemical analysis for tin. Where the amount of tin is less than 0.02 %, it shall be permissible for the analysis to be reported as<0.02 %.

For Grade 50S [345S], the maximum permissible carbon equivalent value shall be 0.47 % for structural shapes with flange thickness over 2 in. [50 mm], and 0.45% for other structural shapes. The carbon equivalent shall be based on heat analysis. The required chemical analysis as well as the carbon equivalent shall be reported. The carbon equivalent shall be calculated using the following formula:

![]()

Materials and Manufacture

1. For all Grades, the steel shall be killed.

2. For Grades 50W[345W], HPS 50W [HPS 34W],and HPS 70W[HPS 485W], the steel shall be made to fine grain practice.

3. For Grade 50S[345S], the steel-making practice used shall be one that produces steel having a nitrogen content not greater than 0.015 % and includes the addition of one or more nitrogen-binding elements, or one that produces steel having a nitrogen content of not greater than 0.012 % (with or without the addition of nitrogen-binding elements). The nitrogen con-tent need not be reported, regardless of which steel-making practice was used.

4. For Grades HPS 50W[HPS 345W], HPS 70W [HPS 485W] and HPS 100W[HPS 690W], the steel shall be made using a low-hydrogen practice, such as vacuum degassing during steel making; controlled soaking of the ingots, slabs; controlled slow cooling of the ingots, slabs, or plates, or a combination thereof.

5. For Grade HPS 100W[HPS 690W], the requirements for fine austenitic grain size in Specification A6/A6M shall be met.

6. Grades HPS 50W[HPS 345W] and HPS 70W[HPS 485W] shall be furnished in one of the following conditions: as-rolled, control-rolled, thermo-mechanical control processed(TMCP) with or without accelerated cooling, or quenched and tempered.

7. For fracture critical base material only, weld repair of the base metal by the material manufacturer or supplier is not permitted.

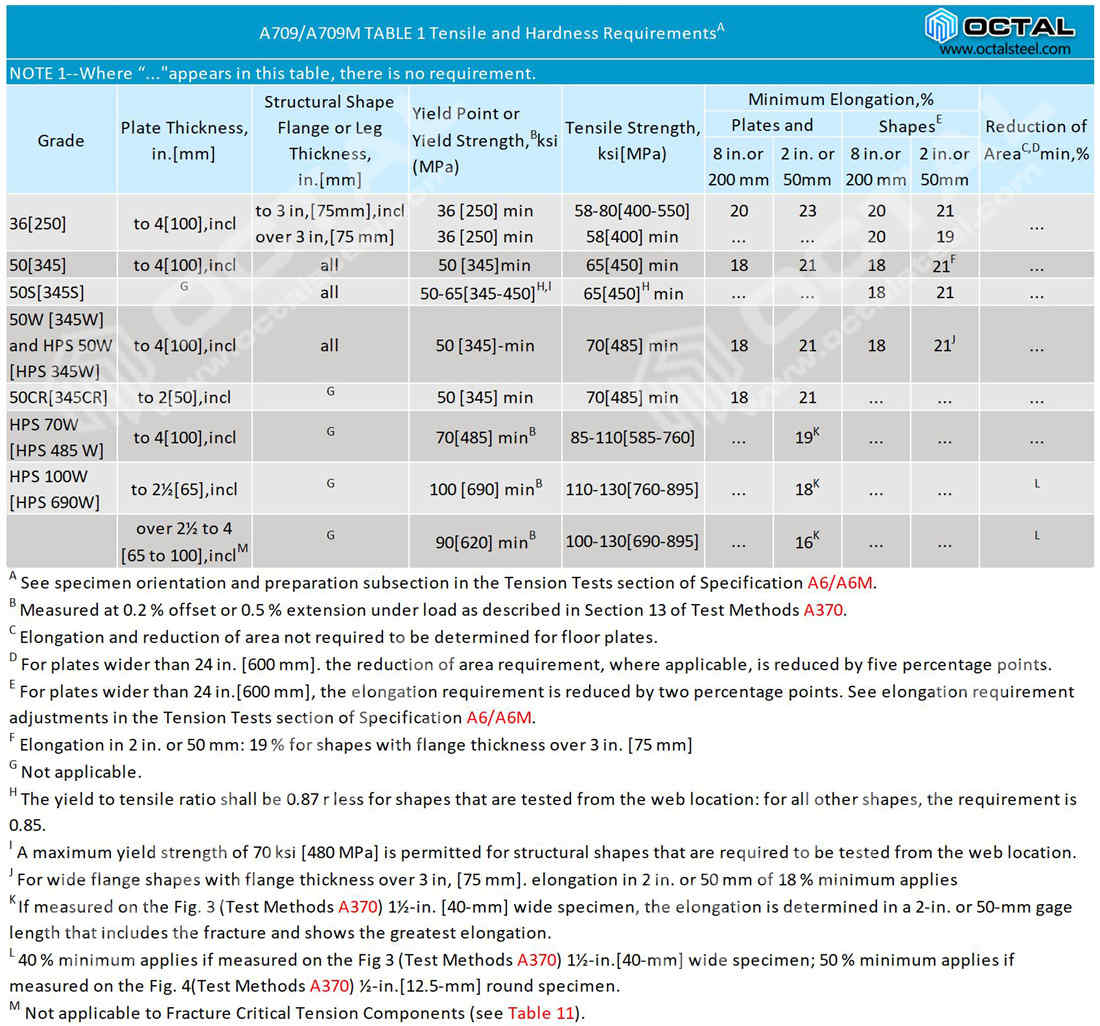

Tensile Strength and Hardness Strength

Heat Treatment

1. For quenched and tempered Grades HPS 50W[HPS345W] and HPS 70W[HPS 485W], the heat treatment shall be performed by the manufacturer and shall consist of heating the steel to no less than 1650°F[900C], quenching it in water or oil, and tempering it at no less than 1100°F [590°C]. The heat-treating temperatures shall be reported on the test certificates.

2. For Grade HPS 100W [HPS 690W] the heat treatment shall be performed by the manufacturer and shall consist of heating the steel to a temperature in the range from 1600 to 1700°F[870 to 925C], quenching it in water, and tempering it at no less than 1050°F[565°C] for a time to be determined by the manufacturer. The heat-treating temperatures shall be reported on the test certificates.

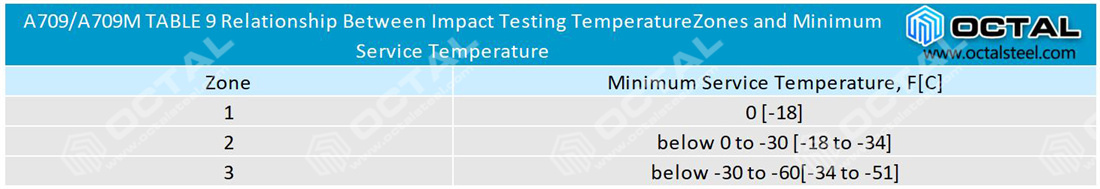

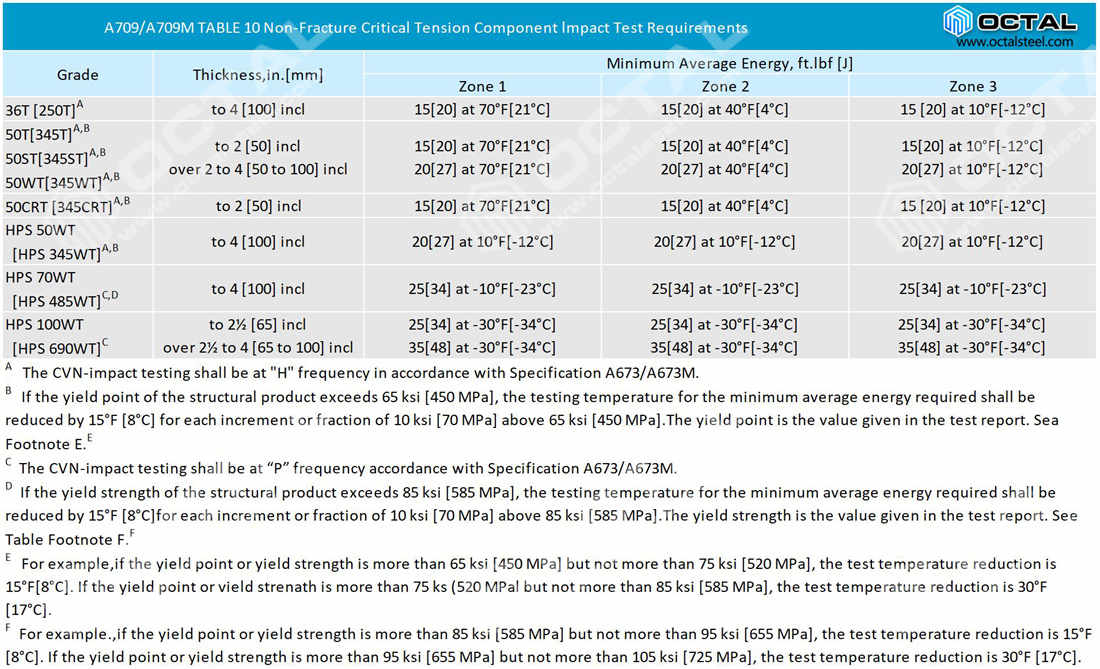

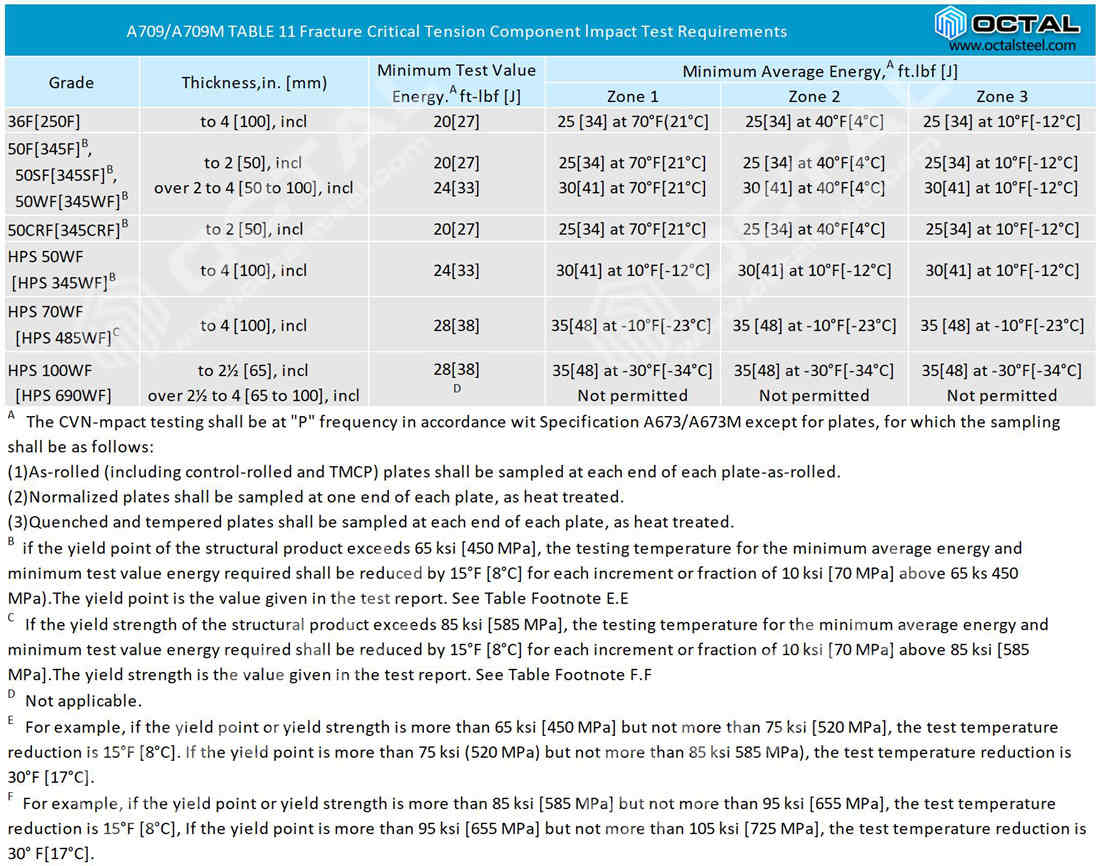

Impact Testing Temperature

Non-Fracture-Critical, T Tension Components-Structural products ordered for use as tension components of non-fracture-critical members shall be impact-tested in accordance with Specification A673/A673M and as given in Table 10. The test results shall meet the requirements given in Table 10.

Fracture-Critical, F Tension Components–Structural products ordered for use as tension components of fracture-critical members shall be impact tested in accordance with Specification A673/A673M and as given in Table 11. The test results shall meet the requirements given in Table 11.

Our Supply Range for ASTM A709 Plates

Octal provide ASTM A709 low alloy high strength steel plate as follow:

Standard: ASTM A709

Grades: 36, 50, 50S, 50W, HPS 50W, HPS 70W, and HPS 100W

Thickness Range: 6 – 100 mm

Width Range: 900 – 4800 mm

Length Range: 3000 – 12000 mm

Steel Cutting Services: Flame Cutting Steel, Laser Cut Steel, Waterjet cutting steel sheet, Plasma Cutting.