ASTM A691 2-1/4CR Pipe Specification

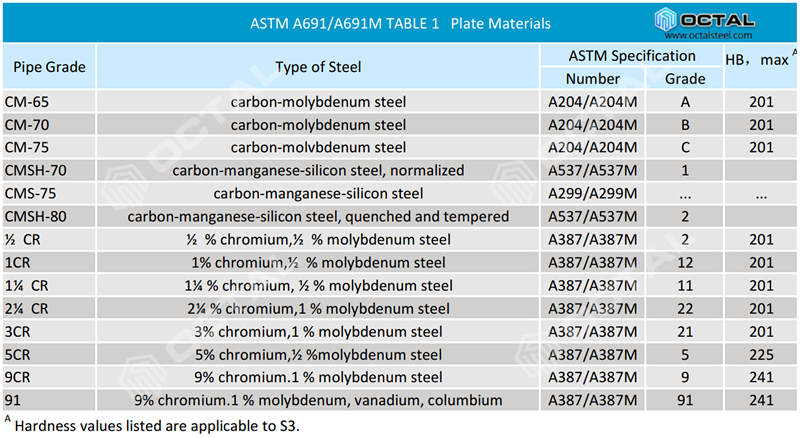

Standard and Grades: ASTM A691 1-1/4CR, 2-1/4CR, 2-1/4CR, 3CR, 5CR, 9CR, 91

Material types: Chrome Moly Welded Pipe

Manufacturing types: EFW Electric-Fusion-Welded

Sizes: 16” to 60”

Wall thickness: SCH 2o, SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, up to 3 inch

Length: 6 meters, 12 meters or customized.

Surface treatment: Painted, Natural, 3PE, FBE

ASTM A691 2-1/4CR pipe refers Chrome Moly Welded Pipe used for high temperature and high pressure services. These pipes are manufactured in Electric-Fusion-Welded process, and fabricated with Chrome Moly Steel Plate in ASTM A387 Grade 22.

ASTM A387 specification covers chromium-molybdenum alloy steel plates intended primarily for welded boilers and pressure vessels designed for elevated temperature service.

Equivalent material in other forms

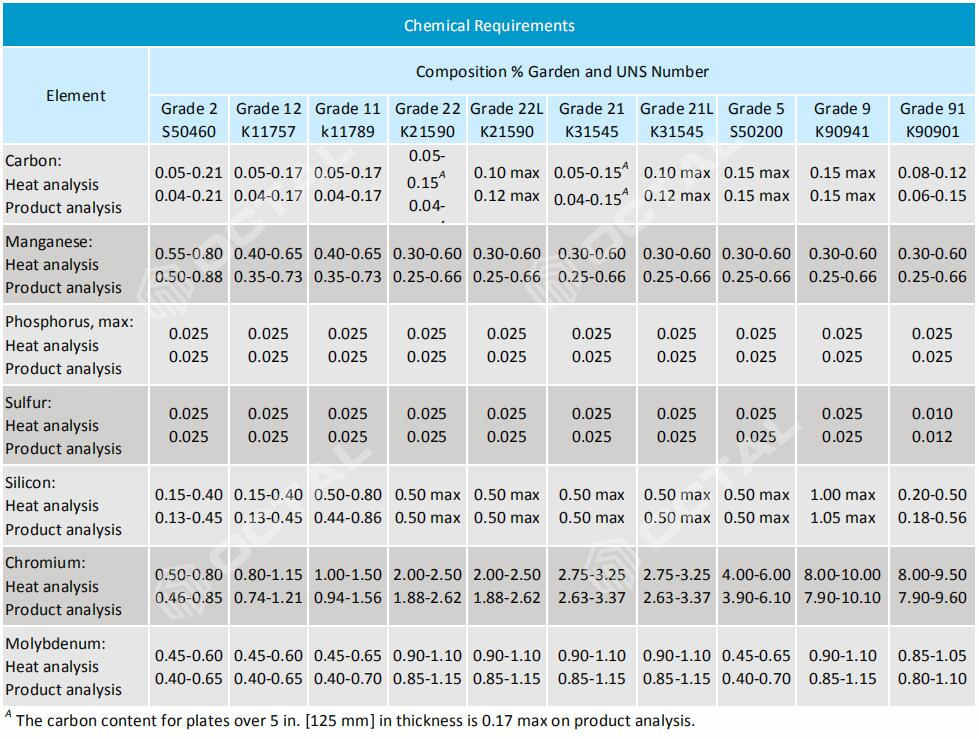

ASTM A691 2-1/4CR pipes has Chrome content 2% to 2.5%, Moly 0.9% to 1.1%. This material equivalent to seamless pipe in ASTM A335 P22 pipe, and also could be made to fittings like elbws, bends, tees, reducers etc.

Pipe fittings standard: ASTM A234 WP22

Flange Standard: ASTM A182 F22

Raw Steel Plate Standard: ASTM A387 Grade 22/ ASME SA387 Grade 22

ASTM A691 Standard Specification

ASTM A691 specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures. Heat treatment may or may not be required to attain the desired mechanical properties or to comply with applicable code requirements. Supplementary requirements are provided when additional testing or examination is needed.

Referred Documents of ASTM A691

ASTM A20/A20M Specification for General Requirements for Steel Plates for Pressure Vessels.

ASTM A204/A 204M Specification for Pressure-Vessel Plates, Alloy Steel, Molybdenum

ASTM A299/A 299M Specification for Pressure Vessel Plates, Carbon Steel, Manganese-Silicon

ASTM A370 Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM A387/A387M Specification for Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum

ASTM A435/A435M Specification for Straight-Beam Ultrasonic Examination of Steel Plates

ASTM A537/A 537M Specification for Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel

ASTM E709 Guide for Magnetic Particle Testing

ASTM E 165 Test Method for Liquid Penetrant Examination

Welding

The joints shall be double-welded full-penetration welds made in accordance with procedure and by welders or welding operators qualified in accordance with ASME Boiler or Pressure Vessel Code, Section IX.

The welds shall be made either manually or automatically by an electric process involving the deposition of filler metal.

Radiographic examination is required for full length of each weld of classes X1 and X2, and maybe performed prior to heat treatment.

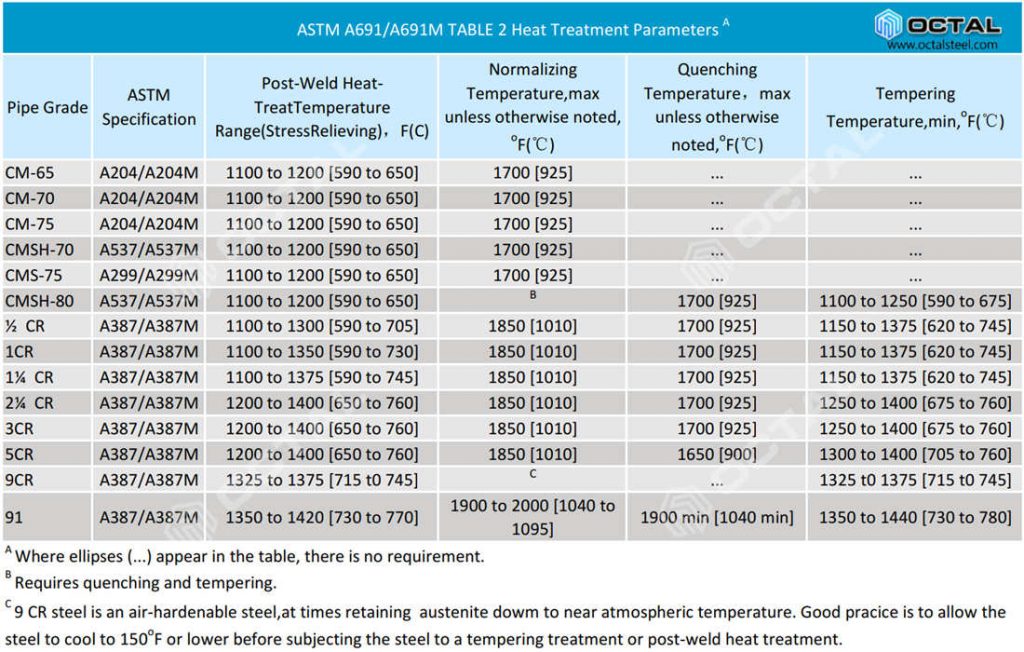

Heat Treatment

All classes other than 10, 11, 12 and 13 shall be heat treated in furnace controlled to 15℃ and equipped with a recording pyrometer so that heating records are available.

Classes 20, 21, 22, and 23 pipe shall be uniformly heated within the post-weld heat-treatment temperature range indicated in Table 2 for a minimum of 1 h/in. Of thickness or 1h, whichever is greater.

Classes 30, 31, 32, and 33 pipe shall be uniformly heated to a temperature in the austenitizing range and not exceeding the maximum normalizing temperature indicated in Table 2 and subsequently cooled in air at room temperature.

ASTM A691 2 1/4CR Chemical Composition

Refers to ASTM A387 Grade 22 / ASME SA387 Grade 22.

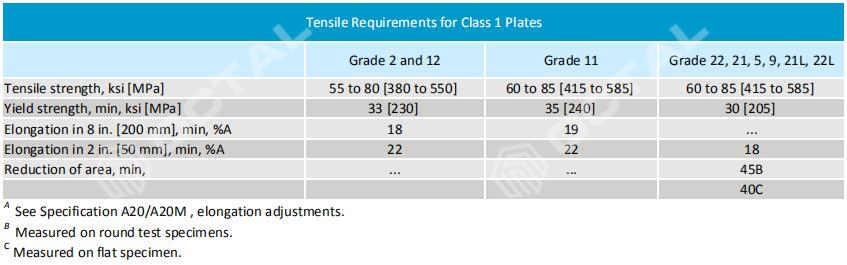

Mechanical Requirements

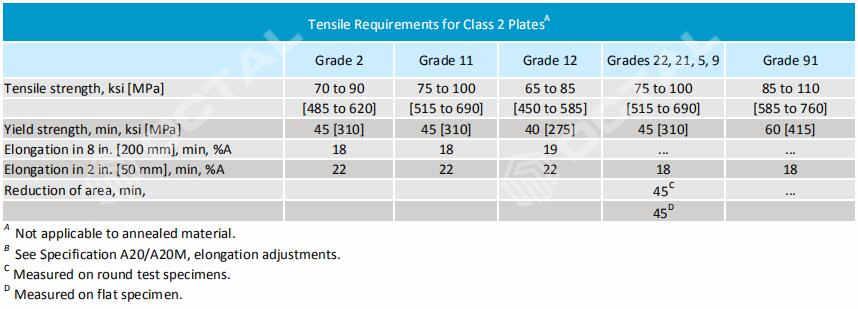

Table 2: For A387 Class 1 Chrome Alloy Steel Plates:

Table 3: For A387 Class 2 Alloy Steel Plates:

Mechanical Requirements

Tensile Test – Transverse tensile properties

Transverse Guided Weld Bend Tests

Hydrostatic pressure test classes X2 and X3 pipe shall be tested in accordance with Specification A530/A530M.

Charpy V-Notch Test for pipe with nominal wall thickness of 1/2in 13mm and greater.

Hardness tests

Metallography

Magnetic Particle Examination of base metal and weld metal

Liquid Penetrant Examination of base metal and weld metal

Ultrasonic Test

ASTM A691 2 1/4CR Permissible Variations

Outside diameter +/- 0.5%.

Out of roundness – The difference between major and minor outside diameters 1%.

Alignment – Using a 10-ft 3m straightedge placed so that both ends are in contact with the pipe, 1/8in. 3mm.

Thickness – Minimum wall thickness at any point in the pipe shall not be more than 0.01 in 0.3mm under the specified nominal thickness.

Lengths with unmachined ends shall be within -0, +1/2 inch, 0 +13mm of that specified. Lengths with machined ends shall be as agreed between manufacturer and purchaser.

Dimension range:

ASTM A691 covers pipe OD in 16inch and above, wall thickness up to 3inch, 75mm.

Stock and Supply Range:

Standard and Grades: ASTM A691 1-1/4CR, 2-1/4CR, 2-1/4CR, 3CR, 5CR, 9CR, 91

Material types: Chrome Moly Welded Pipe

Manufacturing types: Welded

Sizes: 16” to 60”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, up to 3 inch

Length: 6 meters, 12 meters or customized.

Surface treatment: Painted, Natural, 3PE, FBE

Ends: PE (Plain End), BE (Beveled Ends)