ASTM A335 P22 Pipe Specification (Chrome Moly Pipe)

ASTM A335 P22 / ASME SA335 Grade P22

Chrome Moly Alloy Pipe in Seamless

Seamless pipe by hot rolled or cold drawn with proper heatreatment

Sizes: 1/2” to 24”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Ends: PE (Plain End), BE (Beveled Ends)

ASTM A335 P22 Pipe (ASME SA335 P22) is Chrome Moly Alloy Pipe in seamless used for high-temperature services, P22 Grade Pipe Chrome content at 1.90% to 2.60%, Moly content 0.87% to 1.13%, Minimum tensile strength 415MPa and yield strength 205Mpa.

Equivalent Material for Fittings, Flanges, Plates

Pipe fittings standard: ASTM A234 WP22

Flange Standard: ASTM A182 F22

Steel Plate Standard: ASTM A387 Grade 22/ ASME SA387 Grade 22

Welded pipe standard: ASTM A691 2-1/4 CR

P22 pipe material has high toughness and high wear and tear resistance, it could be used to manufacture pipe fittings like elbow, tee, reducers in ASTM A234 WP22 chrome moly pipe fittings.

ASTM A335 Standard Specification

ASTM A335 specificaton covers nominal wall and minimum wall seamless ferritc alloy-steel pipe intended for high-temperature services. The pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar formtion operations, and for fusion welding. Selection will depend upon design, mechnical properties, service conditions and high-temperature characteristics.

Ferritic steels in this specification are defined as low-and intermediate-alloy steels containing up to and including 10% chromium.

Referred standards for making ASTM A335 P22 Pipe

a. ASTM A999/ A999M, Standard specification for common requirements for stainless and alloy steel pipe

b. ASTM A92, Hardness test methods for steel materials

c. E213, Instructions and practice for ultra sonic testing of steel pipe and tube

d. E309 Eddy-Current Examniation methods for steel pipe products

e, E381, Inspection methods for steel bars, beams, profiles, billets and forgings.

f, E527, Numbering metals and alloys practices

g, E570, Instructions for flux leakage examniation of ferromagnetic steel pipe products

Dimension standard: ASME B36.10M

Manufacturing process: Hot finished or Cold drawn

Heat treatment methods:

Full or isothermal anneal or normalize and temper or subcritical anneal

Normalize and temper

Tests

Tensile tests: Transverse and Longitudinal

Flattening test

Hardness test

Bend Test

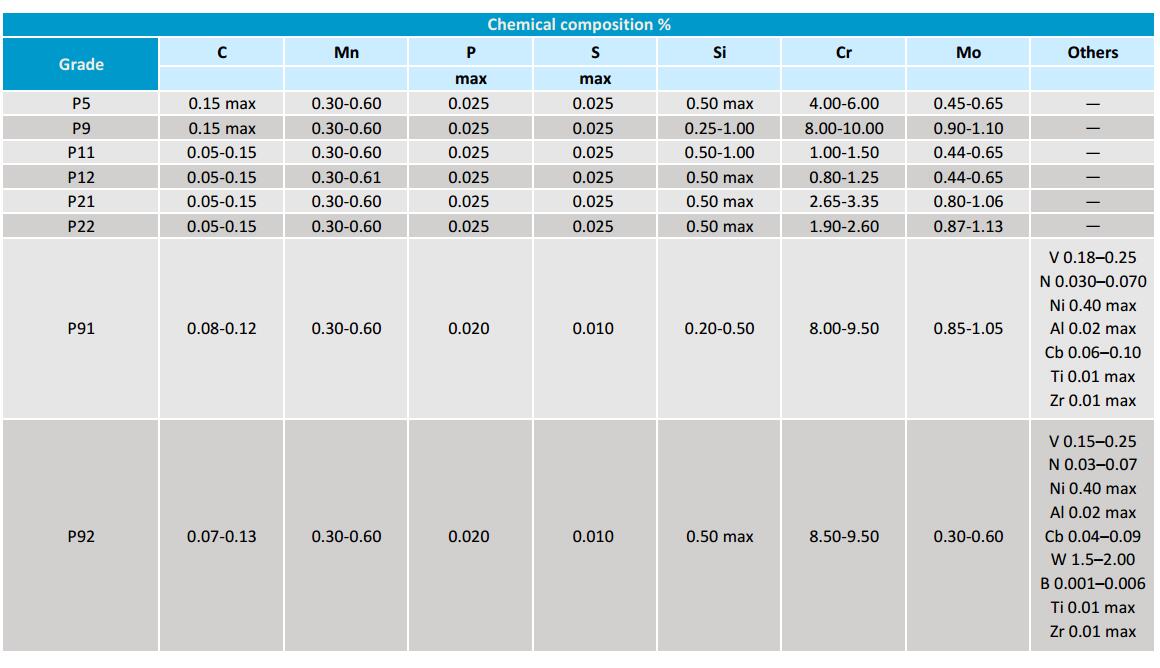

ASTM A335 P22/ASME SA355 P22 Chemical Composition

Chemical Composition and for other P grade Pipe

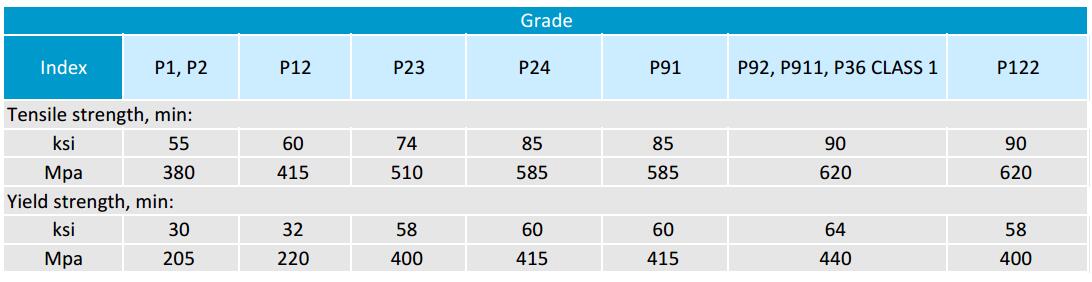

ASTM A335 P22 Mechanical Properties

Elongation: Longitudinal 30% or Transverse 20% for pipe thickness above 8mm.

Chrome Moly Alloy ASTM A335 pipe

ASTM A335 pipe called chrome moly pipe as they have a high level of Chromium and Molybdenum presence in it. While Molybdenum increases the overall strength, resistance, elasticity, hardenability and overall quality, moly ensures that the material is more resistant to softening, restrains the growth of grains and lessens the chances of embrittlement. It is the single additive that is responsible for the increase in high temperature resistance (to 540-750°C) and it also improves the corrosion resistance to steel.

Key Elements – Chromium

Chromium is a key component that is used in the manufacture of stainless steel. If the chromium levels are above 12%, it can be classified as stainless steel. The oxidation resistance potential of chrome is irreplaceable even in elevated temperatures. The hardness, tensile and yield strength is better at standard temperatures. Due to the composition of the material, it is ideal to be used in power plants, refineries, petro-chemical plants and other oil field services when there is transportation under high temperatures and pressures involved.

ASTM A335 P11, P22 – Common Use Grade

ASTM A335 P11 and P22 are most common use in Chrome Moly Alloy Pipes for high temperature environment, for power industry and petro-chemical plants.

Our Supply Range

Standard and Grades: ASTM A335 / ASME SA335 Grade P11, P22, P5, P9, P11

Material types: Chrome Moly Seamless Alloy

Manufacturing types: Seamless pipe by hot rolled or cold drawn

Sizes: 1/2” to 24”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Surface treatment: Polished, Varnished, 3PE, FBE

Ends: PE (Plain End), BE (Beveled Ends)