What is OCTG? It includes Drill Pipe, Steel Casing Pipe and Tubing

OCTG is the abbreviation of Oil Country Tubular Goods, it mainly refers to the piping products that are applied in oil and gas production (drilling activities). OCTG pipe is normally manufactured based on API or related standard specifications. It could also be taken as a collective name for Drill pipe, Steel Casing Pipe and Tubing pipe, Couplings, Connections, and Accessories, used in petroleum industries both onshore and offshore.

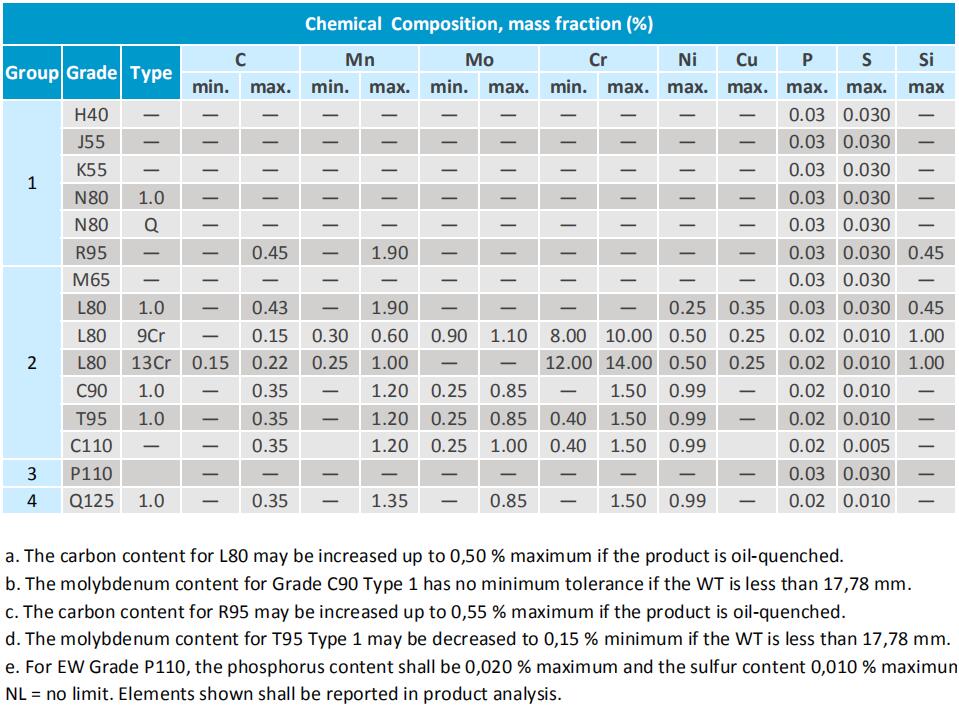

According to the API (American Petroleum Institute) standardized specifications, through the control of the chemical properties and adopting different heat treatments, OCTG pipe is classified into different performances material with more than ten grades.

Types of Oil Country Tubular Goods (OCTG pipes)

There are three main types of Oil Country Tubular Goods, which include Drill pipe, Casing pipe, and Tubing pipe.

To give you a better understanding, we will explain the meaning of each of the three to help you understand their work and their use.

OCTG Drill pipe – Pipe for Drilling

Drill pipe is a heavy, seamless tube that rotates the drill bit and circulates drilling fluid. It allows the drilling fluid to be pumped through the bit and back up the annulus. The pipe can withstand axial tension, extremely high torque and high internal pressure. That is why the pipe is extremely strong and vital in OCTG endeavour.

Drill Pipe normally means the Durable steel pipe used in drilling, standards in API 5DP and API SPEC 7-1.

If you don’t understand the annulus of oil well, it is the space between the casing and the piping or any piping tubing, casing or piping immediately surrounding it. Annulus allows the fluid to circulate in the well. So when we are talking about strong or heavy-duty OCTG pipe, we are talking about Drill pipe.

Steel Casing pipe – Stabilize the wellbore

Steel casing pipe is a type of pipe used in the construction of wells, particularly in the oil and gas industry. It is used to line the borehole that is being dug into the ground to get oil. Just like the drill pipe, the steel pipe casing can also withstand axial tension. This is a large-diameter pipe inserted into a drilled borehole and held into place with cement. The casing is subject to the axial tension of its dead weight, the external pressure of the rock surrounding it, and the internal pressure of the purging fluid. When it is well cemented in place, the drilling process is aided in the following ways:

1. Structural Support: Casing sticks the drill string and prevents unstable upper formation from caving in, provide structural integrity to the wellbore, preventing it from collapsing during drilling and production.

2. Isolation: It prevents water well zone contamination, they isolate different geological formations to prevent the migration of fluids between them. This is crucial for maintaining the integrity of the well and protecting groundwater resources.

3. Protection: Casing provides a smooth internal bore for the installation of production equipment, safeguards the well from external contaminants and environmental factors, and ensures that the extracted resources remain uncontaminated. It also seals off high-pressure zones from the surface, preventing fluid loss in production areas.

4. Facilitating Production: Casing allows for the installation of production tubing and other equipment necessary for extracting oil or gas from the well.

Casing pipes are typically made from steel and come in various sizes and grades, depending on the specific requirements of the well and the conditions it will encounter, it is an extremely heavy-duty pipe vital to OCTG.

Casing and Tubing Manufacturing Video

OCTG Casing Pipe standard

Steel Casing pipe standards usually referred to API 5CT, Common Grades in J55/K55, N80, L80, C90, T95, P110 etc. Common length in R3 which nominal at 40 ft / 12 meters. Casing pipe ends connection types are usually in BTC and LTC, STC. And premium connections are also required in large quantities in an oil and gas piping project.

Steel Well Casing Pipe Price

Steel Casing Pipe cost is lower than drill pipe or the OCTG tubing cost, it is usually higher 200 USD than the regular API 5L pipe. Considering the Threading + Coupling cost or the heating treatment.

OCTG Tubing Pipe – Transporting Oil and Gas to the Surface Ground

OCTG Tubing pipe is a type of pipe used in the oil and gas industry, specifically within wells, to transport fluids (such as oil, gas, or water) from the production zone to the surface. Tubing is the simplest part of OCTG and it is normally found in the segment of 30 ft (9 m), with threaded connections at both ends. The pipe is either used to transport natural gas or crude oil from the producing formation to the facilities where it will be processed after drilling is complete. Here are some key characteristics and functions of tubing pipe:

1. Fluid Transport: Tubing serves as the conduit for the extracted fluids, allowing them to flow from the reservoir to the surface facilities for processing and storage.

2. Smaller Diameter: Tubing pipes typically have a smaller diameter compared to casing pipes, which allows for efficient flow rates and easier handling during installation.

3. Pressure Resistance: Tubing is designed to withstand the pressures encountered during production, ensuring safe and reliable transport of fluids.

4. Installation: Tubing is installed inside the casing and can be easily removed or replaced if necessary, facilitating maintenance and repairs.

5. Production Optimization: The design and material of tubing can be optimized for specific production conditions, enhancing the efficiency of fluid extraction.

This tubing must be able to withstand pressure during the extraction process and adequately resist loads and deformations that have to do with production and workovers. Just like casing is manufactured, tubing is also manufactured the same way, but an additional upsetting process is applied to make it thicker.

OCTG Tubing pipe standard

Same as casing pipe standard, OCTG tubing in API 5CT is also in the same material grades (J55/K55, N80, L80, P110 etc), but the tubing’s diameters are up to 4 1/2”, and it ends in various types such as BTC, EUE, NUE, and premium. Most commonly, thickened connections EUE.

Tubing Seamless Manufacturing Video

How steel casing pipe and tubing work together

OCTG pipe Casing and Tubing Specifications

Casing and Tubing Chemical composition in API 5CT

API 5CT Casing and Tubing Data Sheet Download

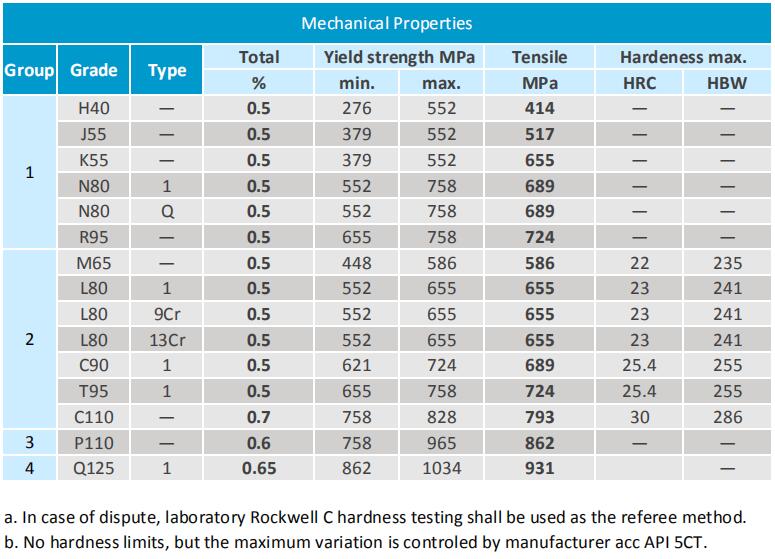

Mechanical Properties Tensile Strength and Yield Strength

Features for OCTG pipe

All OCTG pipes have a standard requirement of dependable hardness. So, whether it is OCTG tubing, OCTG pipe or OCTG drill pipe, there is a certain required standard that is always about super hardness. To meet the standard, manganese and chromium are used as the main alloys to confirm cohesion and durability.

There has been recent developments to eliminate sulfide stress cracking, which is the major problem with manganese and chromium. Alloy and Molybdenum are blended together to overcome the chromium and manganese limitations. So OCTG pipes are now harder than ever, and the fear of sulfide stress cracking has been eliminated.

Looking to buy OCTG Pipe with assured quality at a good price?

Unlike in the past when sulfide stress cracking is a major issue, OCTG pipes are now harder than ever before and are well protected against cracking. If you are looking for the best OCTG distributor, look no further because we – one of the most responsible OCTG distributors – are here.

We make sure our drill pipe, casing and tubing are made to the best quality from guaranteed raw steel material, with competitive prices all over China. All the Oil Country Tubular Goods we supply comply with API standards and are under witness inspection from third parties. They can be used for decades to save your cost in the long run.

As a recognized professional manufacturer, supplier, and distributor, we provide a piping solution for oil and gas companies. Contact us for top-quality OCTG pipe today.