CRA Clad and Lined pipe

CRA cladding or lining material options in:

Stainless material in 304, 304L, 316, 316L, 310S, 317L, 321

Alloy Steel Material in Incoloy Alloy 825 (UNS N08825) , Inconel Alloy 625 (UNS N06625), S31803, S31254

Hastelloy Material C276, (B575 N10276), C22, etc.

External with bonding with Carbon Steel Pipe in API 5L B to X80, or ASTM A106 B, ASTM A333 Grade 6 etc.

CRA (Corrosion resistant alloy) clad pipe and lined pipe applied for the anti-corrosion environment, they have been considered as a new material in the oil and gas pipeline systems. Since they are two kinds of steel material that composite together through bonding processes. (Inner pipe material with expensive stainless 316L or alloy steel Inconel 625, which we called CRA layer. Outer pipe with carbon steel pipe that standards in API 5L or ASTM A106/A53, ASTM A333 Grade 6 etc.)

Clad and lined pipes are specialized types of pipes designed to enhance corrosion resistance and improve performance in various applications. Here’s a brief overview:

Clad Pipes:

- Definition: Clad pipes are made by bonding a layer of corrosion-resistant material (such as stainless steel) to a carbon steel pipe. This combination provides the strength of carbon steel with the corrosion resistance of the outer layer.

- Applications: Commonly used in industries like oil and gas, chemical processing, and power generation, where exposure to corrosive environments is a concern.

Lined Pipes:

- Definition: Lined pipes have a protective lining (often made of materials like PTFE, rubber, or other polymers) applied to the inner surface of the pipe. This lining acts as a barrier against corrosive substances.

- Applications: Frequently used in applications involving the transport of aggressive chemicals, slurries, or other materials that could damage the pipe’s interior.

Key Differences:

- Construction: Clad pipes have a bonded outer layer, while lined pipes have a separate inner lining.

- Purpose: Clad pipes are designed for structural integrity and corrosion resistance, while lined pipes focus primarily on protecting the inner surface from corrosive materials.

CRA clad pipe and lined pipe application

CRA clad and lined pipe generally used in petroleum industries for special working conditions like corrosion or severe temperature environment. For on shore and off shore pipeline systems, there are often contain the high S, H2S, and CO2 chemicals in the transportation fluids. When these values reached a certain content it will make a big corrosion to the pipelines in Carbon and Manganum steel material like API 5L pipes and ASTM A106 pipes. In this case, the CRA clad and lined pipe is applied for this.

CRA Pipe Advantages

CRA material combined with carbon steel material, it is a great achievement for both the mechanical strength (Tensile and Yield strength), meanwhile to have the excellent corrosion resistance performances. No matter on the pipe personality or to save in economic purposes, clad and lined pipe is a perfect choice.

For manufacturing process of CRA clad or lined pipe, there are many bonding methods to mix CRA layer on the steel pipe:

CRA Lined Pipe Mechanical bonding: With machine power pressure or with water pressure;

CRA Clad Pipe Metallurgical bonding: Use exposive power to clad plate comined with steel plate.

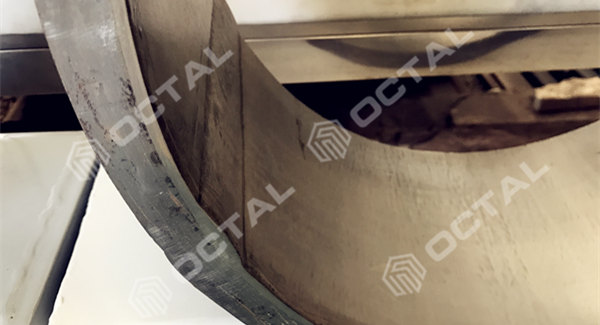

CRA Clad Pipe Welding overlay: Use welding rod (stainless or alloy steel welding rod) to weld a certain thickness on pipe internal surface.

Amoung those types the best performances for bonding is to use welding overlay, but the cost is also the highest, as it takes very slow for welding processes.

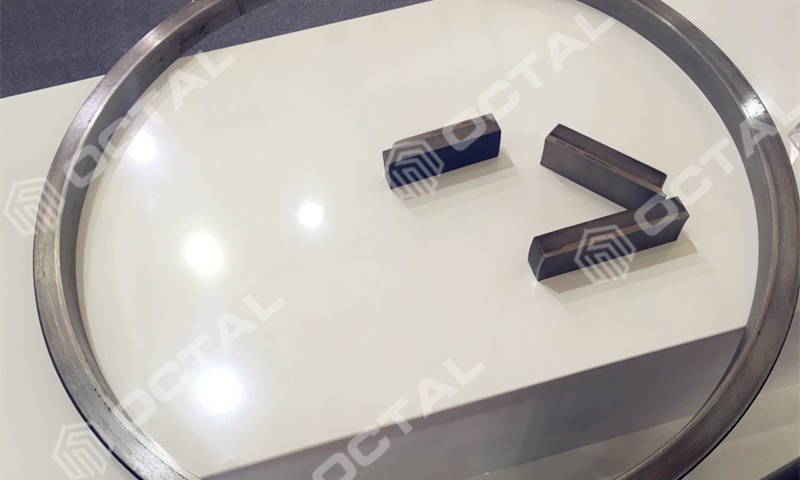

Mechanical lined type

CRA weld overlay type

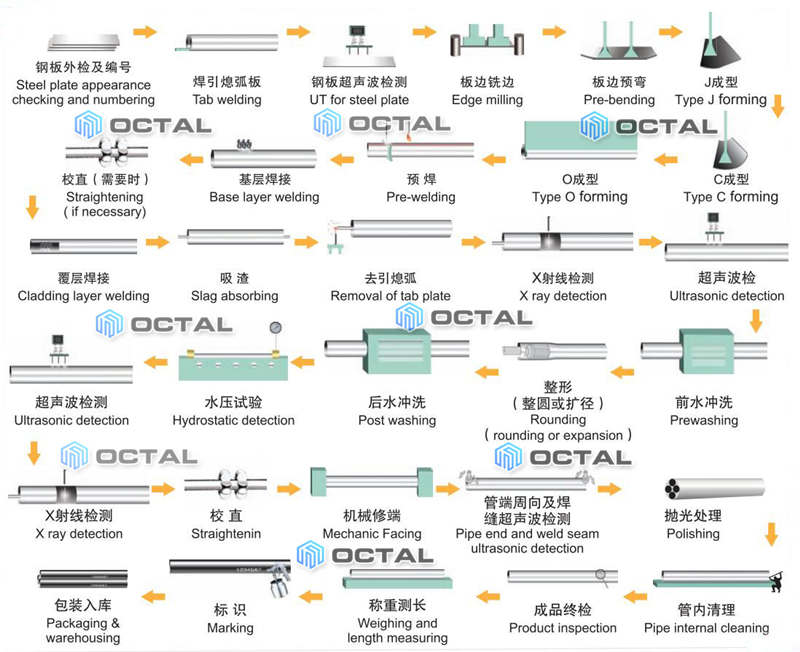

Clad pipe manufacturing process

The point of manufacturing of clad pipe is using metallurgical ways to create the bond. With below manufacturing options:

CRA Clad pipe with exposive power: Use explosive power to clad internal alloy steel pipe to the external carbon steel pipe.

Welding Overlay CRA Clad Pipe: Use welding methods to welding alloy steel rod on the carbons steel pipe.

CRA Clad Steel Plate to weld to CRA pipe: By explosive power to clad alloy steel plate to carbon steel plate, then use LSAW welding process to manufacture plate to CRA Pipe.

Inconel alloy 625 weld overlay / Alloy 625 Cladding / CRA 625 – Popular CRA pipe

Inconel alloy 625 is a non-magnetic, corrosion and oxidation resistant, Ni-Cr based solid solution strengthened deformed superalloy. Nickel alloy 625 is nickel-chromium-molybdenum-columbium alloy, major content Nickel miniumum 58%, also called Inconel 625 or UNS NO6625. Other chemical content Chromimum 20% to 23%, Columbium + tantalum 3.15% to 4.15%, Molybdenum 8.0% to 10.0%, columbium Cobalt allow 1.0% max if determined, Iron 5.0% max.

Inconel 625 is extremely resistant to a variety of unusually severe corrosive environments, including high temperature effects such as oxidation and carburization, including corrosion. Because of the solid solution of the refractory Co and Mo in a Nickel-Chromium matrix, provides 625 an outstanding strength and toughness in high temperature ranging from low up to 2000°F (1093°C).

Use weld overlay cladding methods to clad inconel alloy 625 or alloy 825 material inside of the carbon steel pipe has been a popular option not only solve the corrosion resistant problem to suit different severe environments, but also provides a high strength performances with save a large of cost.

Lined pipe manufacturing methods

For lined pipe is to create through a mechanical bond on the carbon steel pipe. (Put CRA pipe internal to connect to external C-Mn steel pipe through mechanical procedures)

Here are options to manufacture the CRA lined pipe:

Option 1 with external carbon steel seamless pipe internal alloy welded pipe: Outer Pipe (Backing Steel Pipe) Inspection – Cutting – Machining Backing Steel Pipe – Cleaning Inner Surface – Assembling Inner Alloy Pipe – Hydro forming – Cutting Lined Pipe Ends – Beveling – Welding – Sizing pipe End – Forming – RT – ET & Endoscope – Ultrasonic Test – PT – Measuring Size and Inspection – Marking – Packing

Option 2 wtih CRA lined or clad steel plate: Mechanical lined or cladded Steel Plate Checking – UT for Lined Steel plate – Plate Beveling – Preforming – Forming to Pipe (JCOE) – Welding – Rounding – Hydrastatic test – Beveling pipe end – X Ray Test- Ultrasonic Test – Size Inspection and Measuring – Marking – Packing and Storage

Another bonding process of CRA steel pipe is to use a Full-Length Pipe Expander than to use Hydroforming machine. (Between two options a Full-Length-Pipe-Expander is better for bonding CRA material for lined pipe)

Octal supplied CRA clad pipe and lined pipe in below specification

We supply CRA Clad and Lined pipes, Fittings, Flanges:

Clad or Lined standard: API 5LD, API 5LC

Outer Diameter Cladding pipe: 6” to 60”

OD range for CRA lined pipe: 1/2” to 24”

Thickness: Up to 80 mm (Clad pipe), 7 mm to 35 mm (For lined pipe)

Maximum length: 12.3 meter

Backing steel pipe (mother pipe) material: Carbon Steel Pipe, C-Mn Steel Pipe, API 5L B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1, PSL2 and SOUR NACE MR0175, ASTM A106 B, ASTM A333 Grade 6, etc.

CRA Clad Pipe Fittings: Elbow, Cap, Tee, Reducer in ASME B16.9, Material in ASTM A234WPB, WPC, ASTM A420 WPL6.

CRA Clad Flange: Welding Neck Flange, Slip On Flange in ASME B16.5, B16.47 A/B, Material in ASTM A105, A350.

Cladding and Lining CRA (Corrosion resistant alloy) material: Austenitic stainless steel, nickel alloy steel, Hastelloy C276, alloy 625, 825, S31803, S31254 titanium alloy steel duplex steel, and etc.

More over, We are also capable to supply clad pipe fittings and flanges.

CRA Clad or Lined Pipe Order Sample Description & Specification

CRA Clad or Lined Steel Pipe, Carbon steel pipe in ASTM A106 Grade B, Outer Diameter 16 in, Nominal Weight 62.58 lb/ft, Wall thickness Schedule STD. Inner Coating Lining or Cladding HASTELLOY C276 in Thickness 0.125 in / 3mm, External Coating Varnished, Nominal Length 12 Meter (40 FT), Ends Beveled.

Sample Description for Cladding Pipe Fittings Order

Eccentric Reducer, Material Carbon Steel, Standard and Grade ASTM A234 WPB, Ends Design Beveled.

Nominal Diameter 18 in x 16 in, Wall Thickness Sch 40. ASME B16.9 manufacturing standard, External Paint Anti-Corrosion Coating, Internal Coating Cladding 1/8”/3mm thick B575 N10276.

Recent Comments